- Ask a related questionWhat is a related question?A related question is a question created from another question. When the related question is created, it will be automatically linked to the original question.

This thread has been locked.

If you have a related question, please click the "Ask a related question" button in the top right corner. The newly created question will be automatically linked to this question.

Tool/software:

As we all know, the heat dissipation area of the DRV8412 chip is at the bottom of the chip, but in practical applications, if i want to strengthen the heat dissipation of the area where the chip is located, should the heat dissipation be added to the top layer or the bottom layer?

Hello,

The DDW package does have an exposed thermal pad on the bottom of the device to help with more efficient heat dissipation.

The thermal pad on the bottom of the IC can then be soldered directly to the printed circuit board (PCB), using the PCB as a heatsink. For more details see the following app brief: PowerPad Made Easy

The purpose of the exposed thermal pad on the bottom of the IC is to eliminate the need for a heatsink on top of the device. However, if the application calls for additional thermal performance then an external heat sink could be applied to the top of the IC.

Best Practices for Board Layout of Motor Drivers: https://www.ti.com/lit/an/slva959b/slva959b.pdf

Best,

David

Well, David, I'm glad to hear from you.

I would like to further seek your advice. Now I want to heat the PCB by pasting a piece of thermal conductive silicone grease on the board. Since the PCB was designed with a hole in the bottom of the chip connected to the opposite PCB, I am not sure whether the silicone grease attached to the PCB on the side of the chip or the PCB on the back of the chip will be more conducive to heat dissipation.

Best,

Moer Zhu

Hi Moer,

The exposed pad on the bottom of the DRV8412 needs to be soldered down on the landing pad of the PCB. Once this connection is made, adding a thermal silicone grease around the driver should be fine.

If possible, could you send a picture of the board/layout to better understand your setup?

Best,

David

Hi David,

Thanks again for your response. I didn't feel well a few days ago, so I replied to you today.

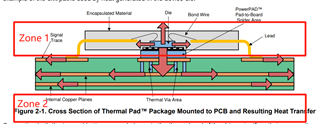

Taking the above picture as an example, if I want to enhance the heat dissipation effect by placing a silicone grease cooling gasket on the PCB board, should this gasket be placed in zone 1 or zone 2?

Best,

Moer Zhu

Hi Zhu,

It should be placed in zone 2, interfacing with bare copper or plated surface without any solder mask. This will help with improved heat dissipation assuming good amount of thermal vias were placed from the top layer all the way to the bottom exposed and plated layer. Thank you.

Regards, Murugavel