Tool/software:

Hello!

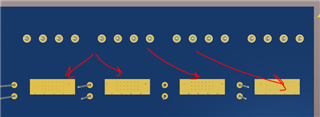

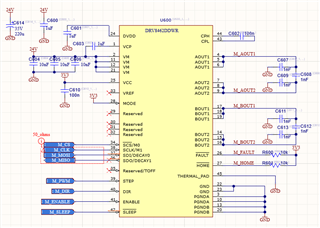

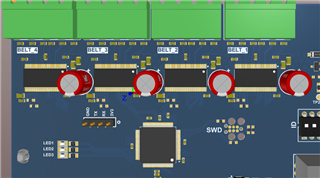

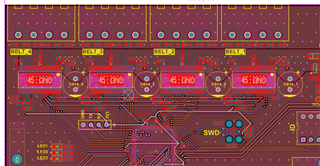

I am developing a board with four 8462DDW drivers whose connections are seen in the image. (In advance, I must say that this is the first time I use stepper motors, so I may not know basic things)

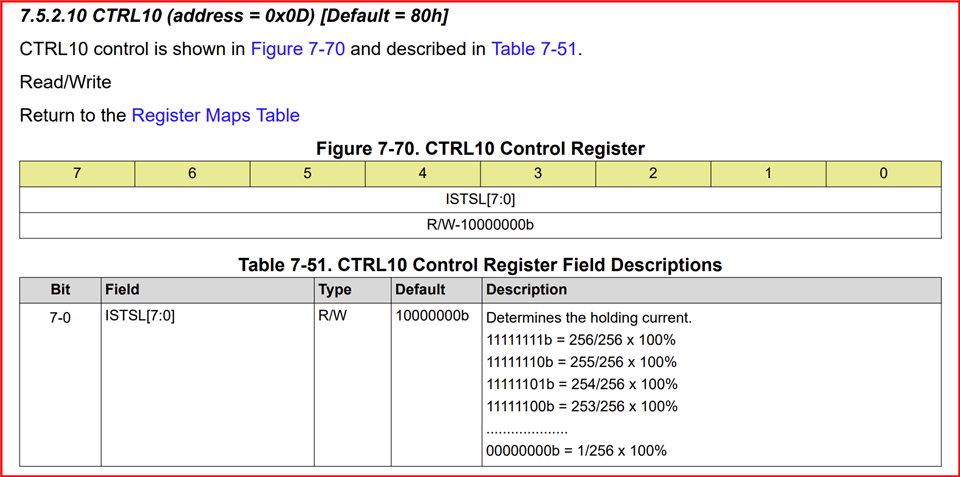

In the Firmware I show you the configuration records of which I am testing:

#define 5 revolutions per seconds

#defin STEP_PER_TURN 200.0

MICROSTEP_MODE = STEP_1_8

TRQ_DAC = 50%

STEP_EDGE = STEP_RISING_EDGE;

VREF_INT_EN = 1;

DECAY = SMART_TUNE_DYNAMIC_DECAY;

The rest of the configuration registers have default values

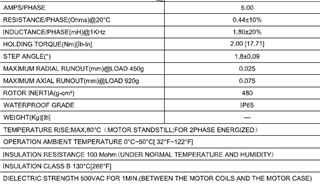

After 2 hours of testing with the motor running the board starts to get very hot, the motor casing is so hot that I can't even touch it. My question are:

Is it normal for engines to get so hot?

What tips are there to reduce heat within settings?

What opinion do you have about the configuration records that I have given you? Tips for optimizing?

Regarding noise: at 2 hours, the engine emits an annoying noise. It's not strong but annoying if you're around it for a long time.

What elements make it more or less noisy?

Some data of the PCB:

- The last layer is GND that dissipates heat through a material that is in contact with a metal.

- It is important to point out that the TRQ_DAC register will be at 50% of maximum current. More torque is not necessary, so it makes no sense to go beyond 70% in my application. (70 is the upper limit)

Greetings to all the members of Texas instruments

I hope you can guide me.