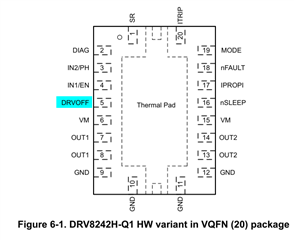

Other Parts Discussed in Thread: DRV8231, DRV8220, DRV8242-Q1, DRV8256, DRV8876-Q1

Tool/software:

Hi,

We have been using the DRV8837CDSGR in the past, and due to our voltage increase to 12.6V, we will need to use the DRV8231A.

What is the difference between the DRV8231A and the DRV8231?

We aim to use the DRV8231A for the following two separate applications:

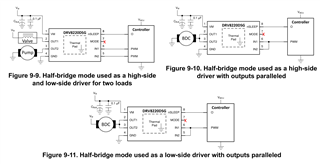

1. **Latching Solenoid:** On the PCB, there would be a requirement for 8 of these. Is there a possibility we could incorporate some type of enable so that only the correct device is controlled by a common IN1 and IN2 signal? With the existing design, we do have 8 separate enable signals available. I guess, in the worst case, I could use one of TI's GPIO buffer ICs.

2. **A small 12V pump rated to 1.5A at max flow:** In the past, we have used a standard driver with protection (IXDI630MYI) for this, but since we will be using the DRV8231A in our inventory, I would like to know if this DRV8231A can also be used for that. This pump has an inductive motor, but bidirectional control is not necessary. Therefore, I guess IN2 can always be low and IN1 can be toggled like an enable? In addition, should the pump's negative wire be connected to one of the outputs connected to GND, or should it be connected directly to the GND?

Thank you.