Hi, I'm trying to use the DRV8802PWPR with the MSP-EXP430G2 launchpad.

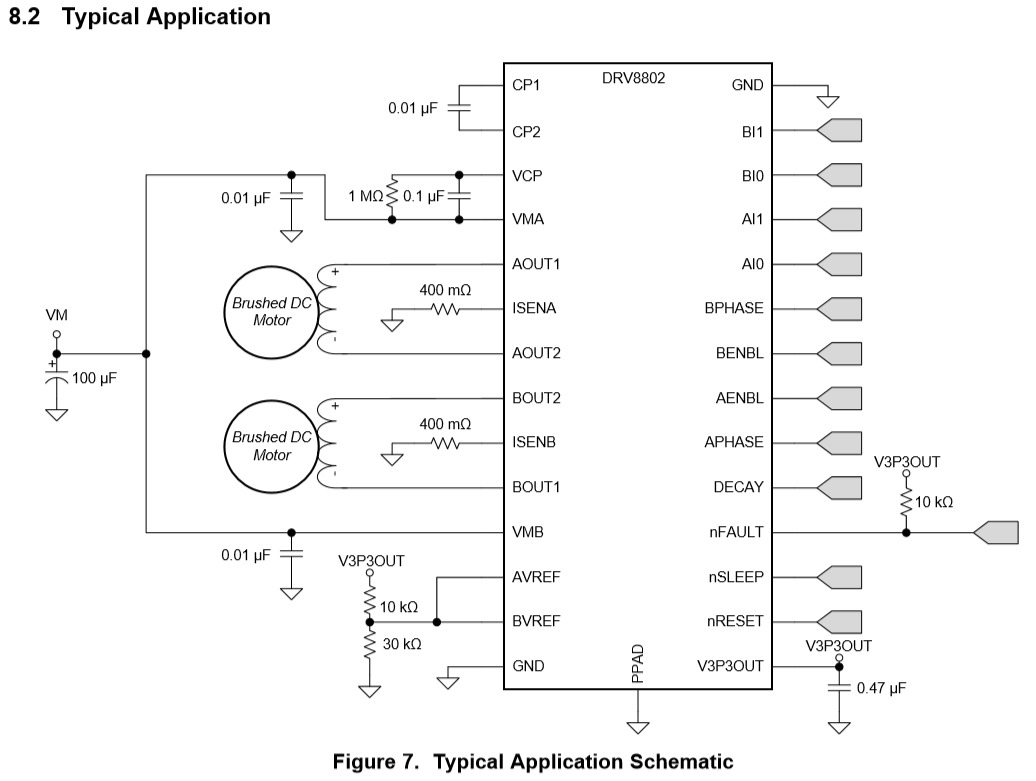

I'm just controlling two DC motors. Since DRV8802PWPR has two outputs, this is perfect for me.

I got some questions.

Q0. Difference between -Q1 products.

I have purchased the DRV8802PWPR from Digikey. Whereas I saw DRV8802QPWPRQ1, which has Q1, is also sold. What is the difference between these two?

Q1. App example

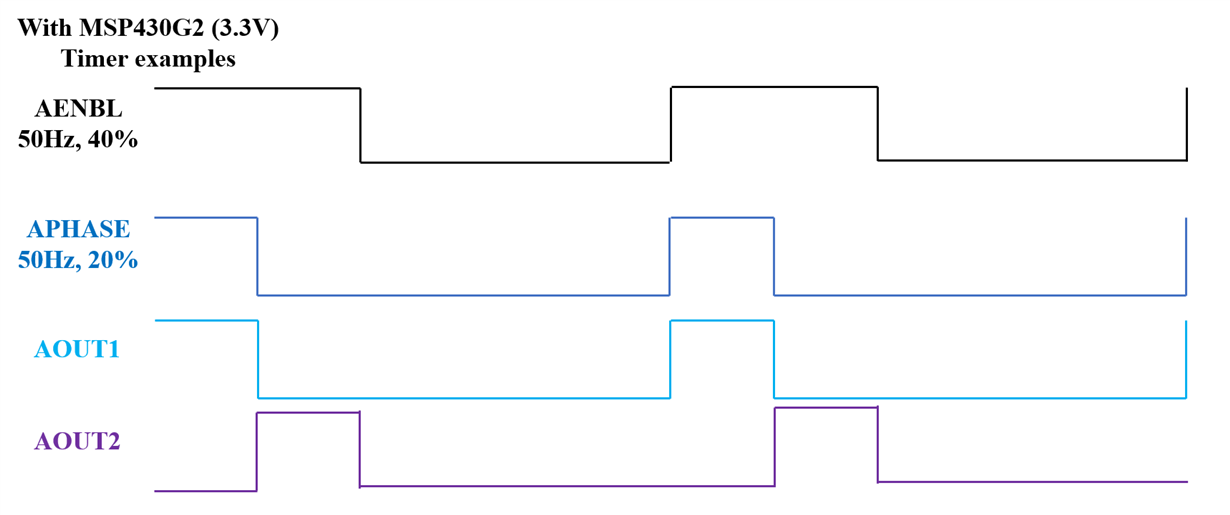

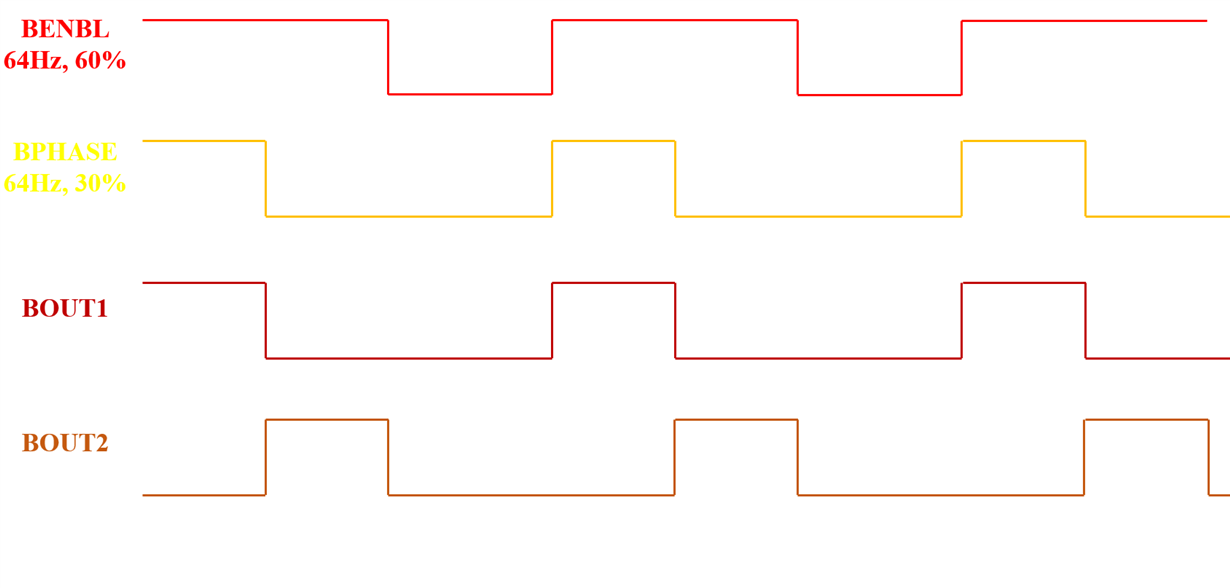

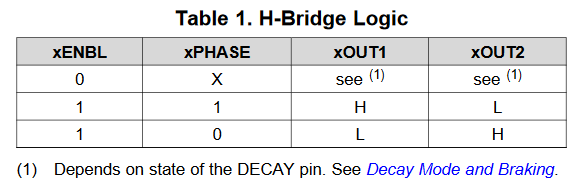

For my case, I only need to control the speed and direction of each motor.

I'm trying to connect 2MHz 15% duty cycle PWM signal on AENBL pin and BENBL pin to control the output duty cycle.

Can AENBL pin and BENBL pin respond to MHz range on/off signals? I cannot find the pin's response from the datasheet.

Q2. I'm having a problem understanding the "Reference voltage for winding current set."

What are a winding current and current chopping?

Q3. ISEN - Connect to current sense resistor for bridge A/B

Why did the above application use a voltage divider for the reference? I'm confused with what reference I should provide.

For my case, I want to limit the current to 400mA for both outputs.