Hi,Ti

Now I am using DRV8303 to drive INFINEON MOS model 028N06NS.

During debugging, it is found that the drive is normal when no load is carried. When load or motor is blocked, the current cannot be added and abnormal sound occurs to the motor, and the blocked current is 0.9A.

It is powered by a 24V lithium battery.

The brushless hall reduction motor has a motor power of 180W and a speed of 2000RPM, and the shaft output speed after reduction is 120RPM.

The attachment is the peripheral circuit of DRV8303. Could you please help to analyze it and see what the problem is?

Problem phenomenon supplement:

1) Control Register 1 is set to 0x1610 and Control Register 2 is set to 0x1804

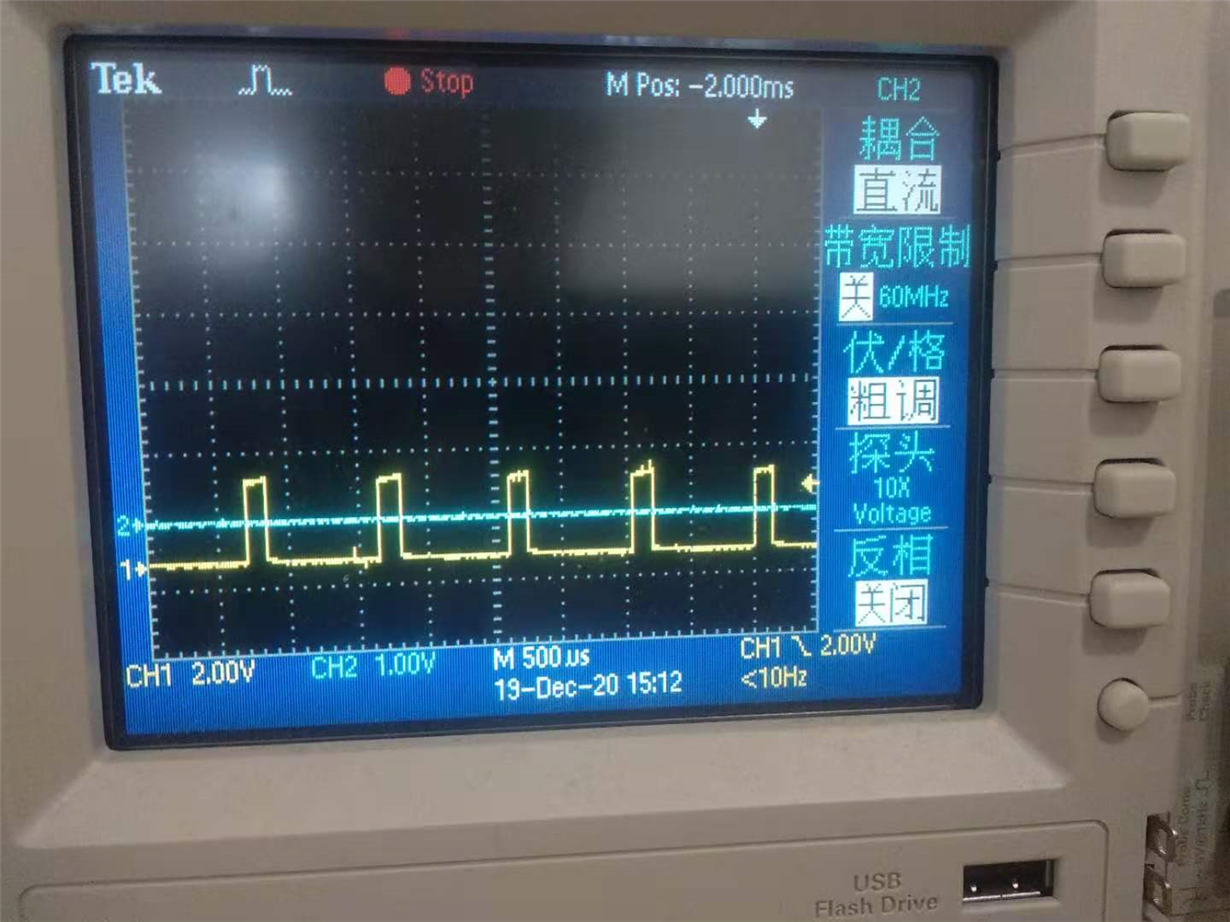

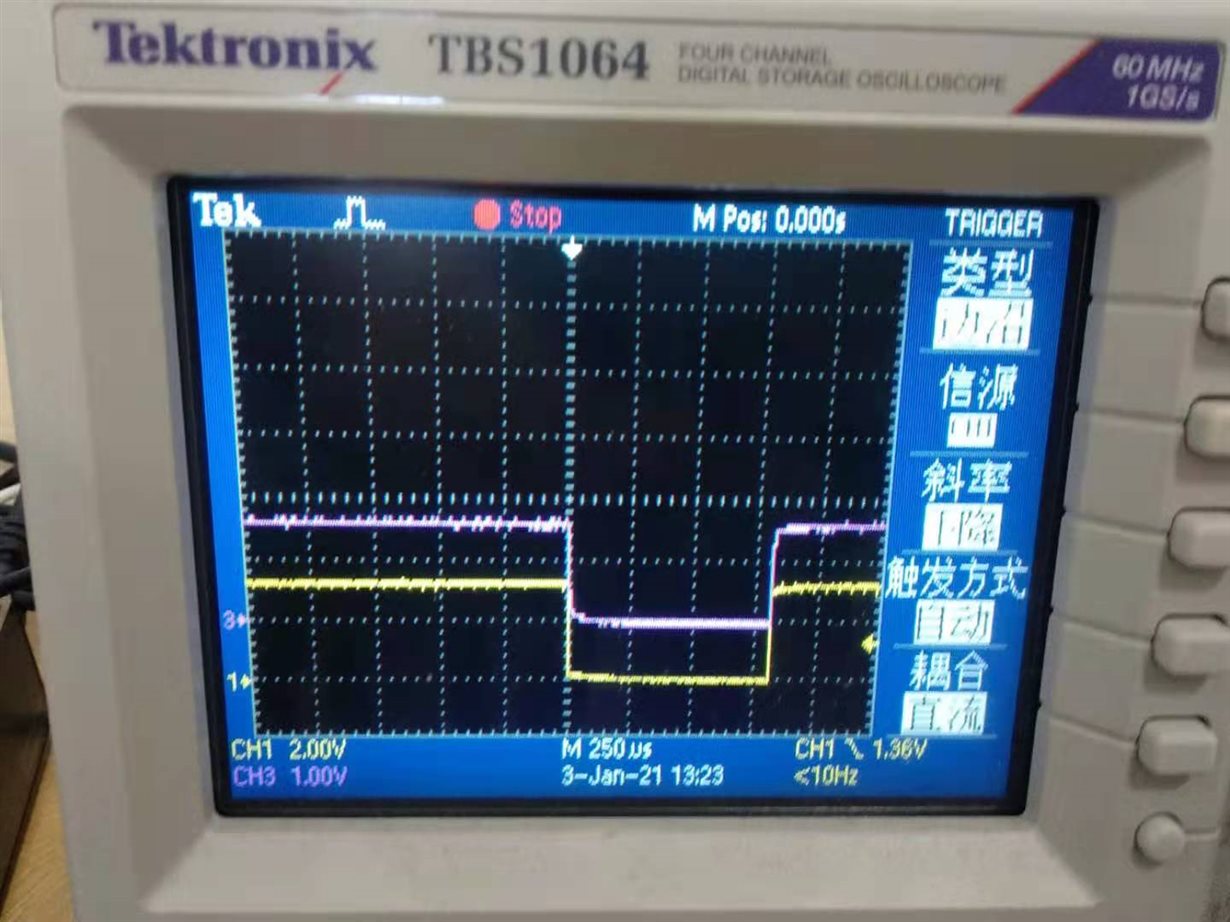

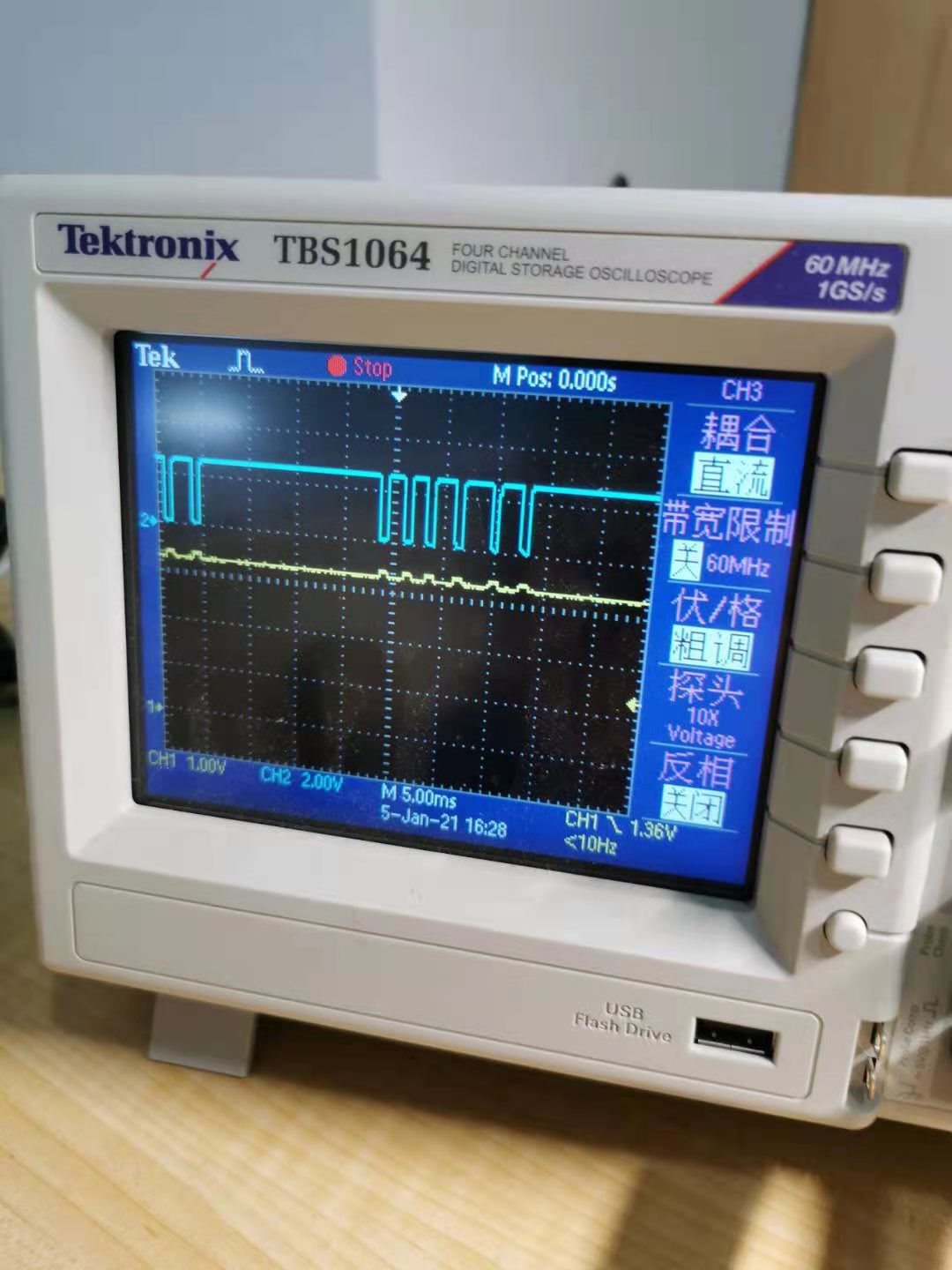

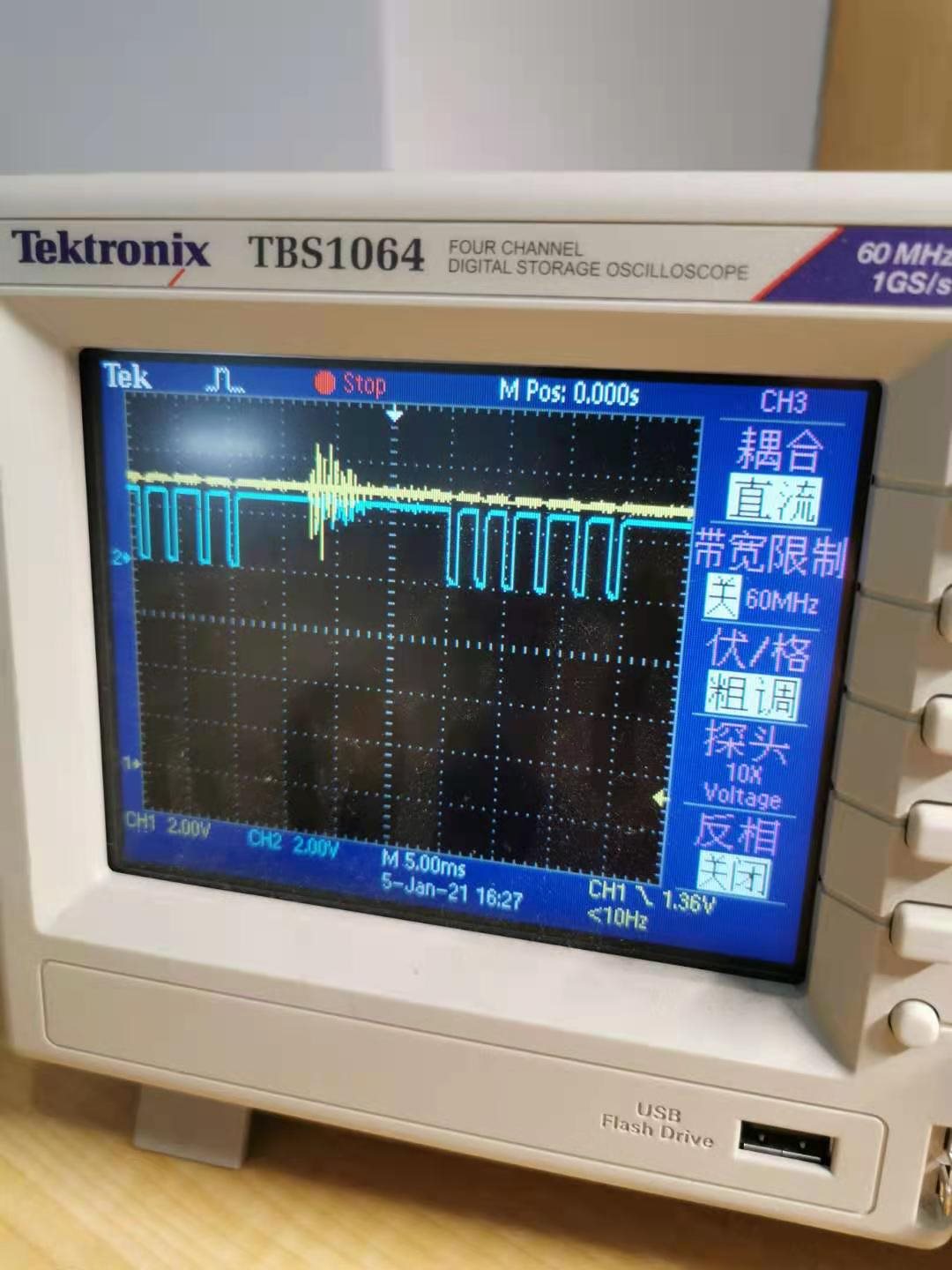

2) When problems occur, the nFAULT pin outputs the periodic signal in the diagram, and the nOCTW pin is always at a high level

3) The pins of DVDD, GVDD and PVDD were observed with oscilloscope without obvious voltage sagMOS028N06NS.pdfDRV8303外围电路.pdf