Hello,

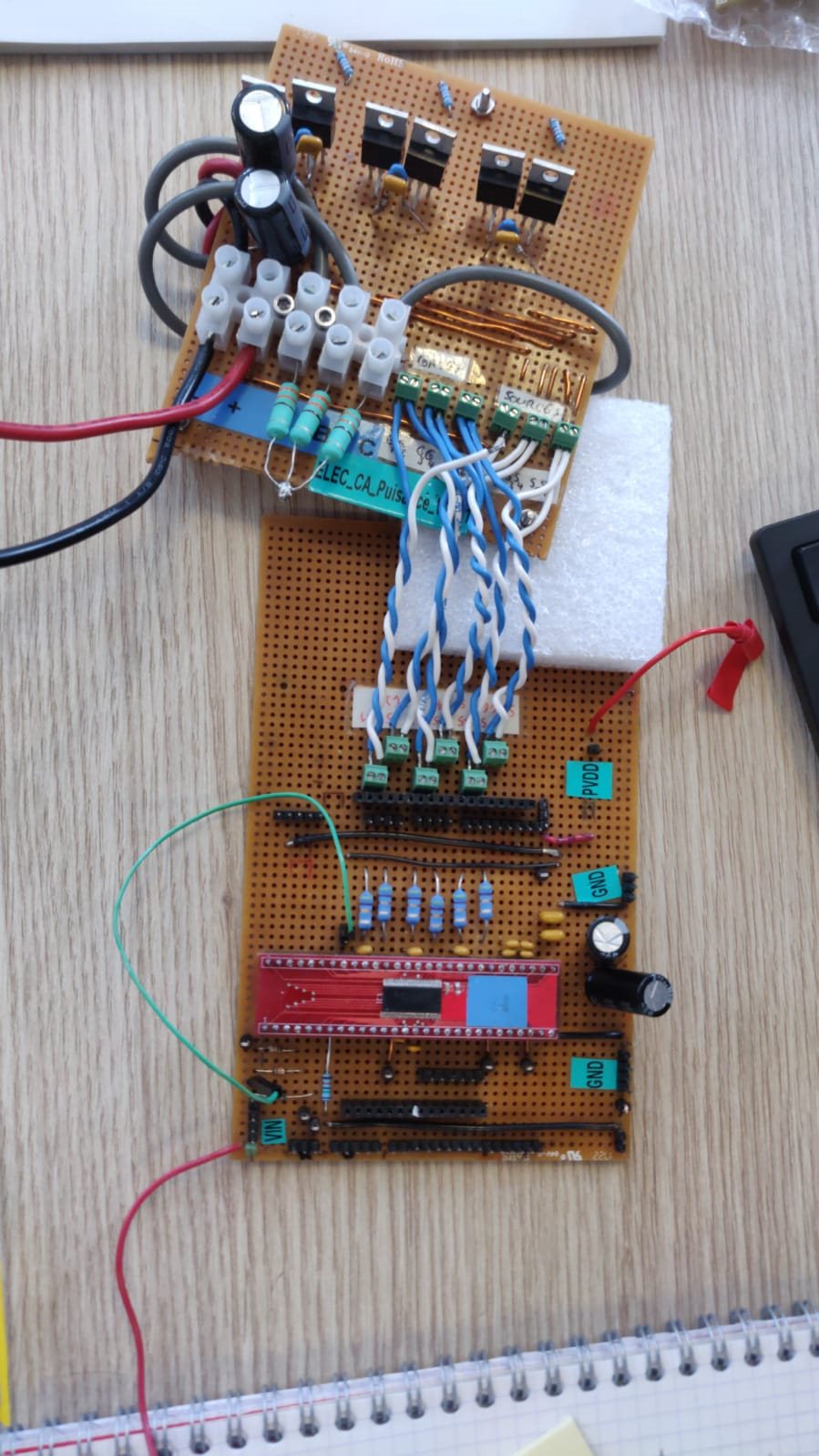

We are three students trying to run a brushless motor with the DRV8301 driver. We use a custom APS6355S motor with sensors (2200W, 190KV, 42V, 55A according to the manufacturer) and IRFB7546 MOSFETs (Vds 60V, Rds 6.0 mOhms, Id 75A). While our system works with simples resistances instead of the phases of the motor (goods signals), when we connect the motor, the motor refuses to move despite an audible wriggling. The driver suffers damage that we do not understand (we note an under-voltage on GVDD). We believe that our problem stems from a hardware configuration error or a wrong/bad realization of our prototype (development board with holes / copper strips).

Our servo procedure is as follows: we gradually increase the duty cycle of the PWM signals sent to the MOSFET gates and the microcontroller is responsible for sending the signals to the right gates according to the position of the motor (normally the algorithm is not the source of the problem). However, after increasing the duty cycle by a few percent, the driver went into error (nFault). We believe that the current draw of the motor when it is started is responsible for this result.

The peak current can go up to around 500A according to our calculations. The driver will therefore go to safety but will that prevent us from running it?

On the other hand, we have observed the presence of noise at a frequency of around 800MHz, the amplitude of which is quite variable, but we are not sure of its origin. By modifying the position of the ground point of our assembly we were able to partially solve this noise problem (less noise).

Is there an error in our assembly or our method? Do you have any specific advice for us?

You can find the entire assembly and the engine datasheet attached.

Thank you so much.