Other Parts Discussed in Thread: DRV8803, EK-TM4C1294XL, , DRV8804EVM

Tool/software: Code Composer Studio

Hello,

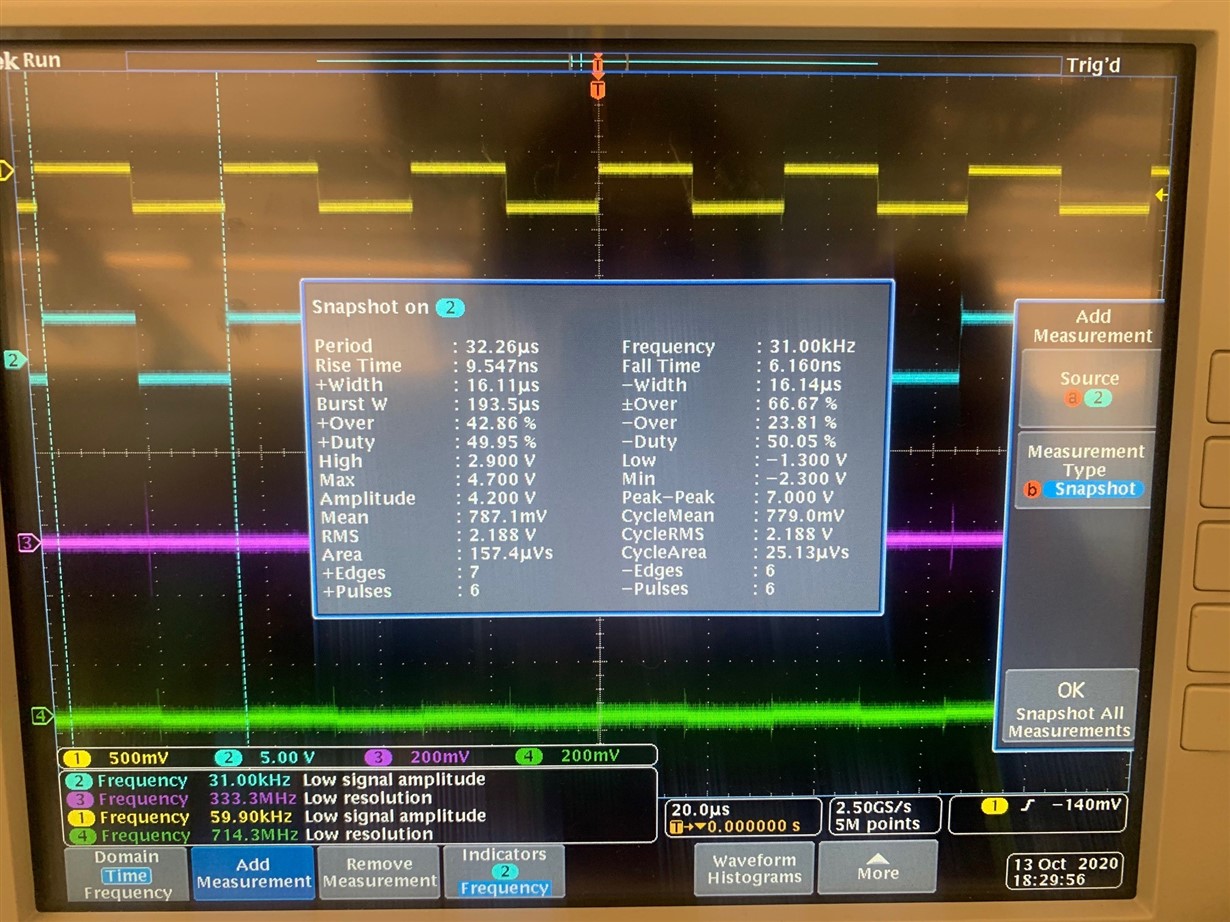

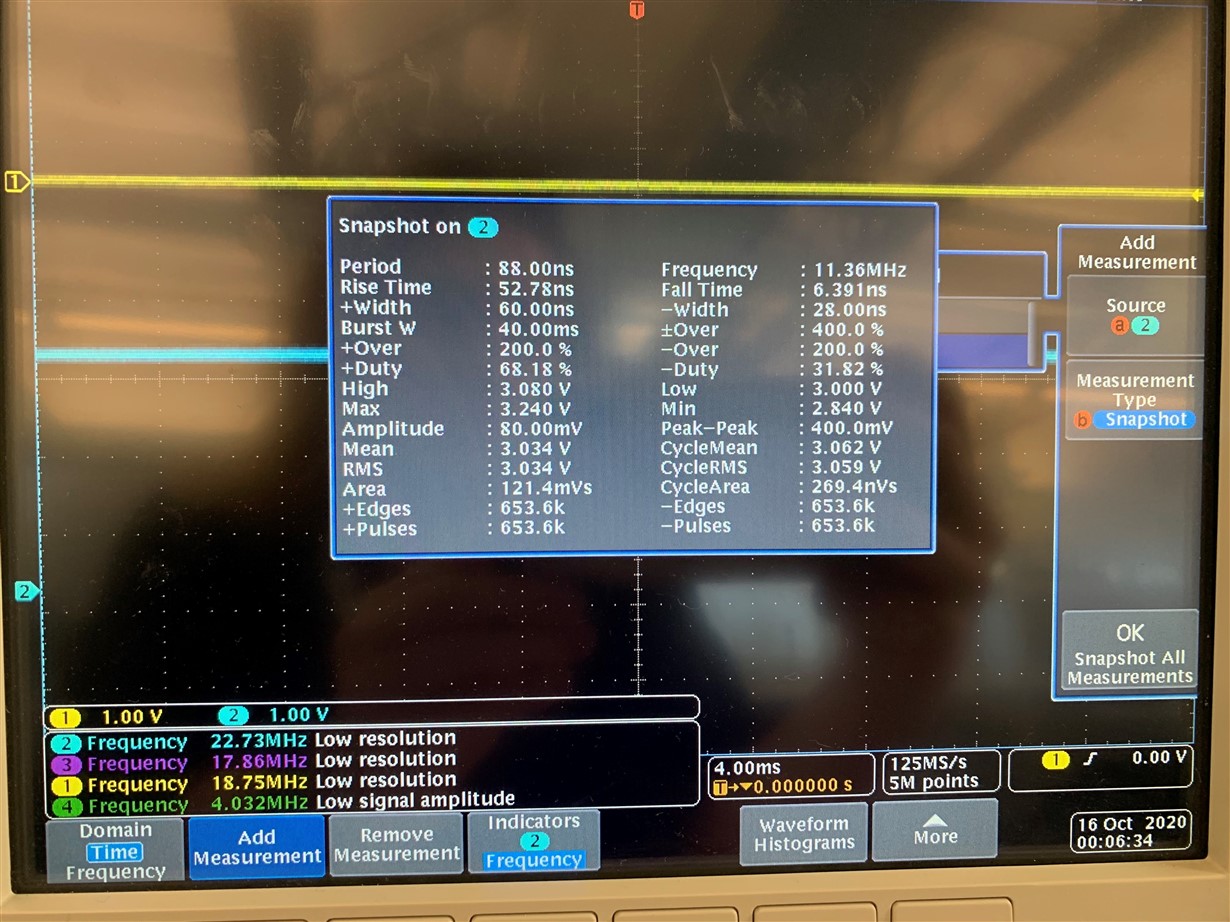

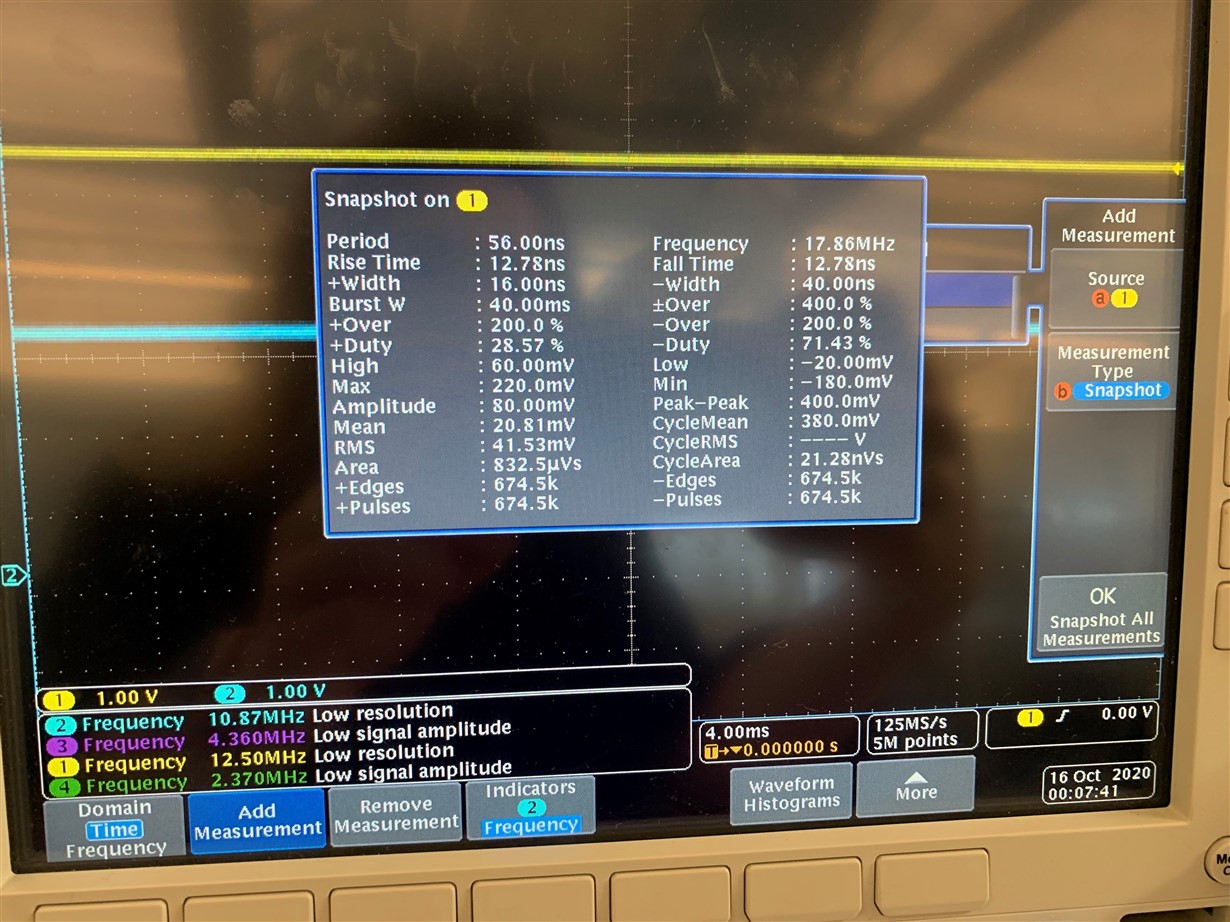

I am trying to write code on the EK-TM4C1294XL that will produce a PWM wave that controls the DRV8803 on the DRV8803EVM board.

What I want to do is use the EK-TM4C1294XL to turn on and off a solenoid using the DRV8803EVM board, according to the DRV8803 datasheets I need to have a PWM to trigger the motor drive function of the DRV8803. On the DRV8803EVM board, I don't want to use the microcontroller because I am applying external signals from the EK-TM4C1294XL. From my understanding of the DRV8803 timing diagram, I need to have a PWM that will stay high until the solenoid needs to be turned on and then the PWM will go low, am I correct in this thinking?

Based on my understanding I have written the code below. However, when I connect the EK-TM4C1294XL to the DRV8803EVM board (which I believe I have set up correctly according to the diagram) I don't get anything from the outputs of the board. I have pasted the code I am using below.

////*****************************************************************************

#include <stdbool.h>

#include <stdint.h>

#include "inc/hw_memmap.h"

#include "driverlib/gpio.h"

#include "driverlib/adc.h"

#include "driverlib/pin_map.h"

#include "driverlib/pwm.h"

#include "driverlib/sysctl.h"

#include "driverlib/uart.h"

#include "utils/uartstdio.h"

//////*****************************************************************************

//////

////// This function sets up UART0 to be used for a console to display information

////// as the example is running.

//////

void

GetADC(void)

{

#if defined(TARGET_IS_TM4C129_RA0) || \

defined(TARGET_IS_TM4C129_RA1) || \

defined(TARGET_IS_TM4C129_RA2)

uint32_t ui32SysClock;

#endif

uint32_t pui32ADC0Value[1];

#if defined(TARGET_IS_TM4C129_RA0) || \

defined(TARGET_IS_TM4C129_RA1) || \

defined(TARGET_IS_TM4C129_RA2)

ui32SysClock = SysCtlClockFreqSet((SYSCTL_XTAL_25MHZ |

SYSCTL_OSC_MAIN |

SYSCTL_USE_PLL |

SYSCTL_CFG_VCO_480), 20000000);

#else

SysCtlClockSet(SYSCTL_SYSDIV_10 | SYSCTL_USE_PLL | SYSCTL_OSC_MAIN |

SYSCTL_XTAL_16MHZ);

#endif

UARTprintf("ADC ->\n");

// UARTprintf(" Type: Single Ended\n");

// UARTprintf(" Samples: One\n");

// UARTprintf(" Update Rate: 250ms\n");

UARTprintf(" Input Pin: AIN0/PE3\n\n");

//

// The ADC0 peripheral must be enabled for use.

//

SysCtlPeripheralEnable(SYSCTL_PERIPH_ADC0);

//

// For this example ADC0 is used with AIN0 on port E7.

// The actual port and pins used may be different on your part, consult

// the data sheet for more information. GPIO port E needs to be enabled

// so these pins can be used.

// TODO: change this to whichever GPIO port you are using.

//

SysCtlPeripheralEnable(SYSCTL_PERIPH_GPIOE);

//

// Select the analog ADC function for these pins.

// Consult the data sheet to see which functions are allocated per pin.

// TODO: change this to select the port/pin you are using.

//

GPIOPinTypeADC(GPIO_PORTE_BASE, GPIO_PIN_3);

//

// Enable sample sequence 3 with a processor signal trigger. Sequence 3

// will do a single sample when the processor sends a signal to start the

// conversion. Each ADC module has 4 programmable sequences, sequence 0

// to sequence 3. This example is arbitrarily using sequence 3.

//

ADCSequenceConfigure(ADC0_BASE, 3, ADC_TRIGGER_PROCESSOR, 0);

//

// Configure step 0 on sequence 3. Sample channel 0 (ADC_CTL_CH0) in

// single-ended mode (default) and configure the interrupt flag

// (ADC_CTL_IE) to be set when the sample is done. Tell the ADC logic

// that this is the last conversion on sequence 3 (ADC_CTL_END). Sequence

// 3 has only one programmable step. Sequence 1 and 2 have 4 steps, and

// sequence 0 has 8 programmable steps. Since we are only doing a single

// conversion using sequence 3 we will only configure step 0. For more

// information on the ADC sequences and steps, reference the datasheet.

//

ADCSequenceStepConfigure(ADC0_BASE, 3, 0, ADC_CTL_CH0 | ADC_CTL_IE |

ADC_CTL_END);

//

// Since sample sequence 3 is now configured, it must be enabled.

//

ADCSequenceEnable(ADC0_BASE, 3);

//

// Clear the interrupt status flag. This is done to make sure the

// interrupt flag is cleared before we sample.

//

ADCIntClear(ADC0_BASE, 3);

//

// Sample AIN0 forever. Display the value on the console.

//

int y;

y=0;

while(y<5)

{

//

// Trigger the ADC conversion.

//

ADCProcessorTrigger(ADC0_BASE, 3);

//

// Wait for conversion to be completed.

//

while(!ADCIntStatus(ADC0_BASE, 3, false))

{

}

//

// Clear the ADC interrupt flag.

//

ADCIntClear(ADC0_BASE, 3);

//

// Read ADC Value.

//

ADCSequenceDataGet(ADC0_BASE, 3, pui32ADC0Value);

//

// Display the AIN0 (PE3) digital value on the console.

//

UARTprintf("AIN0 = %4d\r", pui32ADC0Value[0]);

UARTprintf("\n");

//

// This function provides a means of generating a constant length

// delay. The function delay (in cycles) = 3 * parameter. Delay

// 250ms arbitrarily.

//

#if defined(TARGET_IS_TM4C129_RA0) || \

defined(TARGET_IS_TM4C129_RA1) || \

defined(TARGET_IS_TM4C129_RA2)

SysCtlDelay(ui32SysClock / 12);

#else

SysCtlDelay(SysCtlClockGet() / 12);

#endif

y++;

}

}

//////*****************************************************************************

void

InitConsole(void)

{

//////// //

//////Enable GPIO port A which is used for UART0 pins.

//////// // TODO: change this to whichever GPIO port you are using.

//////// //

SysCtlPeripheralEnable(SYSCTL_PERIPH_GPIOA);

////////

//////// //

//////// // Configure the pin muxing for UART0 functions on port A0 and A1.

//////// // This step is not necessary if your part does not support pin muxing.

//////// // TODO: change this to select the port/pin you are using.

//////// //

GPIOPinConfigure(GPIO_PA0_U0RX);

GPIOPinConfigure(GPIO_PA1_U0TX);

////////

//////// //

//////// // Enable UART0 so that we can configure the clock.

//////// //

SysCtlPeripheralEnable(SYSCTL_PERIPH_UART0);

////////

//////// //

//////// // Use the internal 16MHz oscillator as the UART clock source.

//////// //

UARTClockSourceSet(UART0_BASE, UART_CLOCK_PIOSC);

////////

//////// //

//////// // Select the alternate (UART) function for these pins.

//////// // TODO: change this to select the port/pin you are using.

//////// //

GPIOPinTypeUART(GPIO_PORTA_BASE, GPIO_PIN_0 | GPIO_PIN_1);

////////

//////// //

//////// // Initialize the UART for console I/O.

//////// //

UARTStdioConfig(0, 115200, 16000000);

}

//////*****************************************************************************

#if defined(TARGET_IS_TM4C129_RA0) || \

defined(TARGET_IS_TM4C129_RA1) || \

defined(TARGET_IS_TM4C129_RA2)

uint32_t g_ui32SysClock;

#endif

//////////

//////// //

////// // Set the clocking to run directly from the external crystal/oscillator.

////// // TODO: The SYSCTL_XTAL_ value must be changed to match the value of the

////// // crystal on your board.

////// //

#if defined(TARGET_IS_TM4C129_RA0) || \

defined(TARGET_IS_TM4C129_RA1) || \

defined(TARGET_IS_TM4C129_RA2)

// g_ui32SysClock = SysCtlClockSet((SYSCTL_XTAL_25MHZ| SYSCTL_OSC_MAIN | SYSCTL_USE_OSC), 1200000);

#else

SysCtlClockSet(SYSCTL_SYSDIV_1 | SYSCTL_USE_OSC | SYSCTL_OSC_MAIN |

SYSCTL_XTAL_16MHZ);

#endif

////

uint32_t sysclock;

////

void main()

{

float PWM_FREQ;

float CPU_FREQ;

float pwm_word;

int t;

int i;

InitConsole();

// GetADC();

////

PWM_FREQ = 64000; //31.250kHz

CPU_FREQ = 1000000;

pwm_word = (1/PWM_FREQ)*CPU_FREQ;

sysclock = SysCtlClockFreqSet((SYSCTL_XTAL_16MHZ |

SYSCTL_OSC_MAIN |

SYSCTL_USE_PLL |

SYSCTL_CFG_VCO_480), CPU_FREQ);

// GPIOPinTypeGPIOOutput(GPIO_PORTF_BASE, RED_LED|BLUE_LED|GREEN_LED);

i=0;

while(i<20)

{

SysCtlPWMClockSet(SYSCTL_PWMDIV_1);//Set the clock speed

SysCtlPeripheralEnable(SYSCTL_PERIPH_PWM0); //Enable the correct port

SysCtlPeripheralEnable(SYSCTL_PERIPH_GPIOG);//Enable the GPIO port

GPIOPinTypePWM(GPIO_PORTG_BASE, GPIO_PIN_1);//Define the pine

GPIOPinConfigure(GPIO_PG1_M0PWM5); //Comfigure the pin based on the datasheet

PWMGenConfigure(PWM0_BASE, PWM_GEN_2, PWM_GEN_MODE_DOWN | PWM_GEN_MODE_NO_SYNC);//Set the modes

// UARTprintf("Gen config successful\n");

PWMGenPeriodSet(PWM0_BASE, PWM_GEN_2, 300);

PWMPulseWidthSet(PWM0_BASE, PWM_OUT_5,PWMGenPeriodGet(PWM0_BASE, PWM_GEN_2)/128);

PWMOutputState(PWM0_BASE, PWM_OUT_5_BIT, true);

PWMGenEnable(PWM0_BASE, PWM_GEN_2);

UARTprintf("Running1\n");

// GPIOPinWrite(GPIO_PORTF_BASE, RED_LED|BLUE_LED|GREEN_LED, RED_LED);

// SysCtlDelay(20000000);

i++;

GetADC();

}

t=0;

while(t<20)

{

SysCtlPWMClockSet(SYSCTL_PWMDIV_1);

SysCtlPeripheralEnable(SYSCTL_PERIPH_PWM0);

SysCtlPeripheralEnable(SYSCTL_PERIPH_GPIOG);

GPIOPinTypePWM(GPIO_PORTG_BASE, GPIO_PIN_2);

GPIOPinConfigure(GPIO_PG0_M0PWM4);

PWMGenConfigure(PWM0_BASE, PWM_GEN_2, PWM_GEN_MODE_UP_DOWN | PWM_GEN_MODE_DB_NO_SYNC);

UARTprintf("Gen config successful\n");

PWMGenPeriodSet(PWM0_BASE, PWM_GEN_2, pwm_word);

PWMPulseWidthSet(PWM0_BASE, PWM_OUT_4, PWMGenPeriodGet(PWM0_BASE, PWM_GEN_2)/128);

PWMOutputState(PWM0_BASE, PWM_OUT_4_BIT, true);

PWMGenEnable(PWM0_BASE, PWM_GEN_2);

UARTprintf("Running2\n");

// SysCtlDelay(20000000);

t++;

GetADC();

}

////

}

Any help with this would be much appreciated.

Thank you