Other Parts Discussed in Thread: BQ27411-G1, BQ24250, BQ40Z50, BQSTUDIO, EV2400

Hi Experts,

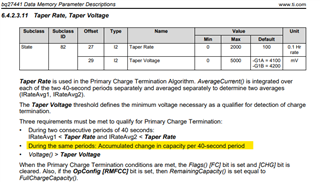

Good day. I have this query from client about Primary Charge Termination Algorithm as described in THIS technical reference.

Customer is using the BQ27441-G1 to measure the SOC of my batteries, they claimed missing info from the reference thinking that IC is not identifying the charge termination. See the snapshot I took:

The second condition is not complete as they reported, and its not clear how the accumulated change in capacity is linked with the algorithm.

Would you please help us clarify this to customer?

Thank you for your support.

Regards,

Archie A.