Other Parts Discussed in Thread: UCC2800

Hi,

This is in reference to PWM Controller IC: UCC2800-EP

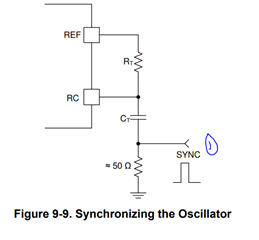

There is a section in the datasheet of the IC where the method is shown to synchronize the PWM controllers (Section 9.3.6). However, it is mentioned that the oscillator of IC is programmed to run at frequency 20% lower than that of synchronizing frequency. In this case if my PWM switching frequency is 120 kHz of FLYBACK, than the external sync pulse should be of 144 kHz? And a positive pulse description is to be applied at 50 Ohm resistor.

But still the picture is not clear, how exactly to design that external sync circuit and what would be the signal characteristics? It's magnitude, duration, or any other considerations regarding its source of generation.

Thanks

Ravi