Hi,

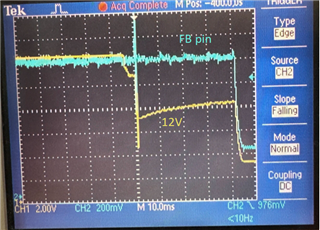

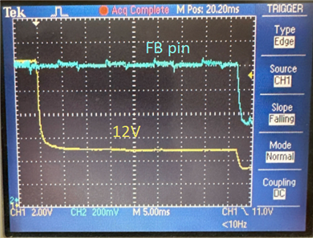

We have an application circuit that fails moisture testing despite having acrylic/urethane conformal coating. (soak in 30-60C 95% moisture for 10days, running fine, it fails (shuts down it self) after taken out to room temperature for 20min, so minor condensation might be present).

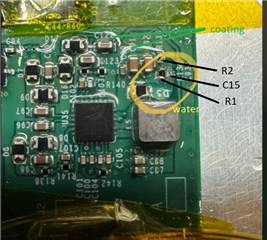

We tried and reproduced the problem by putting a drop of water on the circuit on R1, C15, L1, D1 (conformal coated) (reference to the ref.des. on datasheet) without any load current, the failure happened immediately. This lead us to suspect that the parasitic capacitance of water may be disturbing the circuit and the stability margins may be on the edge. We have been using the recommended values on the datasheet (will list below). To improve stability, we plan to reduce the size of R1, R2 to 160K/16.9K and C15 to ~120pF (haven't test it)

Question: Is there anything else that can help to maximize the stability of the circuit to make it less suspectible to parasitics or external disturbances?

our setup for reference:

Input: 3.3V

Output: 12V, 25V, -10V

L1 = 4.7uF, C9 = 470pF, R9 = 33K, R1 = 820K, R2 = 86.6K, C15 = 22pF,

R3 = 620K, R4 = 75K, R5 = 510K, R6 = 26.1K

Thank you,

Borui