- Ask a related questionWhat is a related question?A related question is a question created from another question. When the related question is created, it will be automatically linked to the original question.

This thread has been locked.

If you have a related question, please click the "Ask a related question" button in the top right corner. The newly created question will be automatically linked to this question.

Hello

we have problems wiith EMC Conducted Emission EN 55014-1 Cond. with TPS7A78.

We have the following component values:

Rs = 330R

Cs = 470nF

CScin = 470uF + 180uF

Csc1 = 1uF

Csc2 = 1uF

CLDOIn = 10uF

To reach compliance we have to increase Rs to 660R and add a X2 Capcitor with 470nF.

This 470nF X2 capacitor is quite big and expensive.

Is there another way to improve conducted Emissions backwards to mains?

Are there some other ways to improve EMI of TPS7A78 with a cheaper and smaller solution?

When we have to use a 470nF X2 capacitor only for TPS7A78 our cost advantage compared to a standard AC/DC converter is too small and then we will not use TPS7A78.

Thanks for help

Hi Christoph,

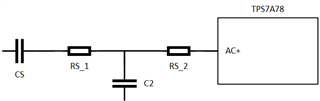

Can you try the network as shown below? Without knowing additional details I cannot derive any values for you, but the Rs is split up among the resistors. You can reduce the X2 capacitor value by taking advantage of the RC filtering from (RS_2 and C2 cap). I would try to reduce C2 to no greater than 220 nF, and lower if possible.

If you need additional support, can you provide some additional details? What is your AC supply, are you operating in half bridge or full bridge configuration, and what is your load? Are you able to show your precompliance test data showing the conducted emissions (and the limit lines) so I can see where the emission data is failing?

Thanks,

Stephen