Other Parts Discussed in Thread: LM5116

Hi,

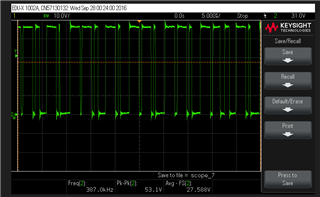

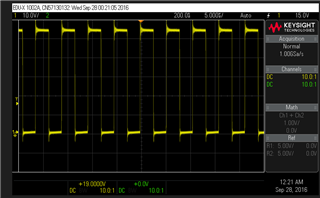

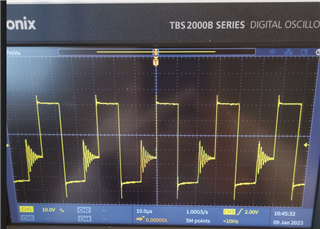

The DC-DC circuits was designed with LM5118, the input voltage range is about 35V-55V, the current load is about 4.2A, I am debugging the board now and found the switching signal has some ring as below waveform shows, the output voltage/current I think is within my expected, noise is somehow worse than my expectation, noise Vp-p is about 2.16V.

My question :

1: how to remove or decrease the switching ring?

2, how to improve the noise

3, I also found the inductor is hot, I measured the temperature of inductor surface under 4A current load, after 30 minutes, the temperature rises to 82 degree C, how to improve this?

The schematic is as below:

Output voltage noise at 4A current load:

...

Thanks

Kelvin