Hi Daniel Li14 & Hongjia-Wu.

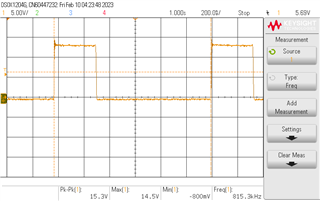

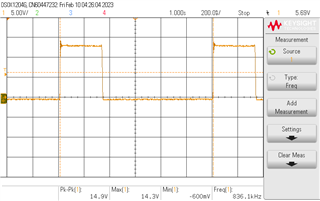

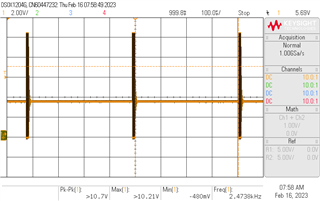

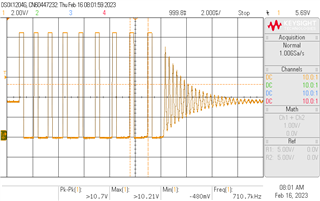

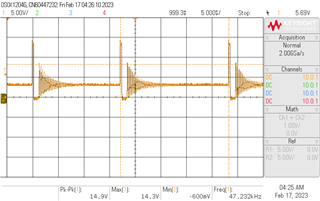

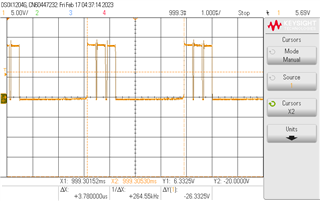

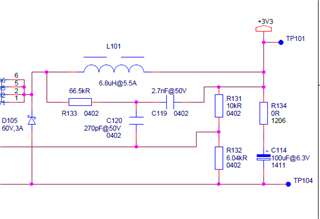

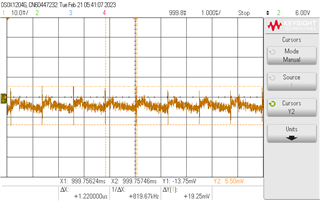

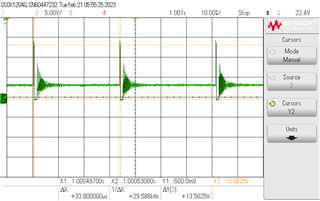

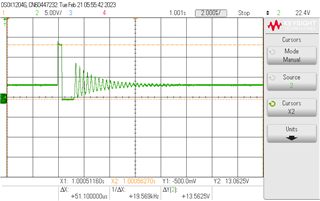

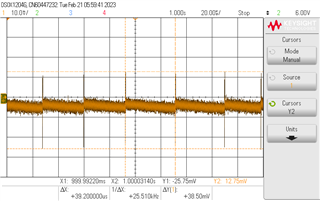

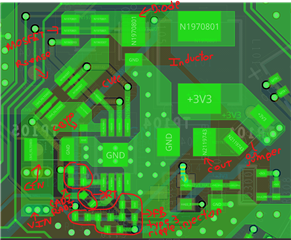

In the new design we are using the type-3 ripple injection way and we did the changes in layout to reduce the loops and system is working fine, working with load (1 A) and no load at 13.5V as input.

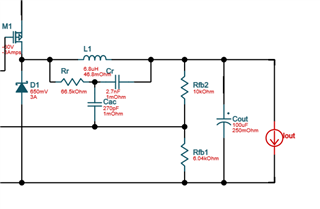

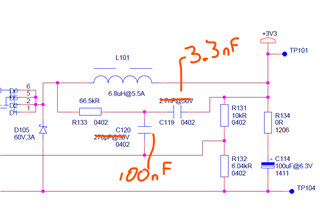

Attached the schematic and new layout we are using.

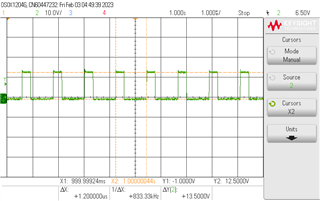

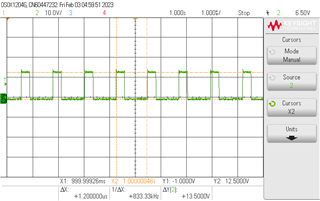

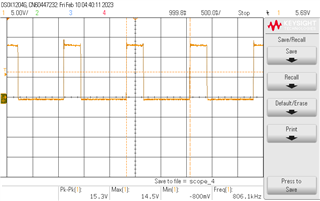

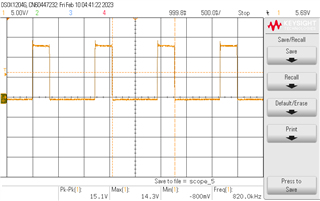

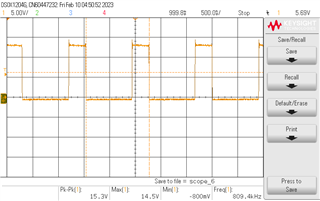

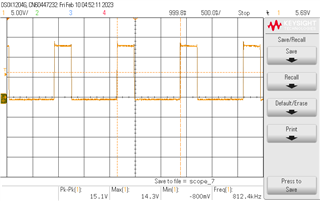

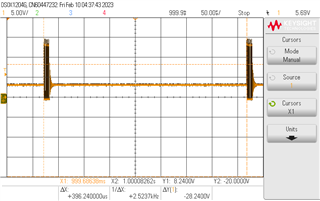

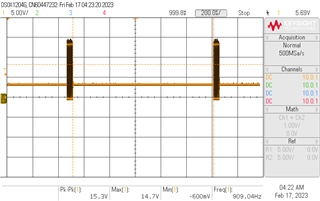

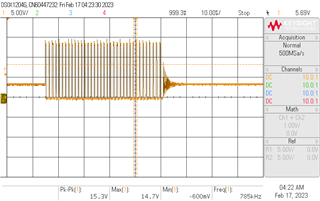

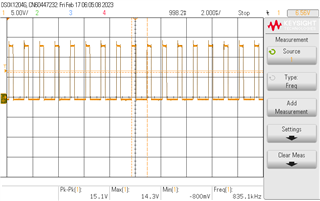

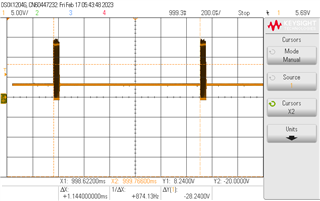

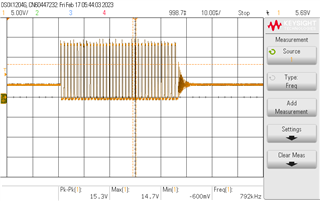

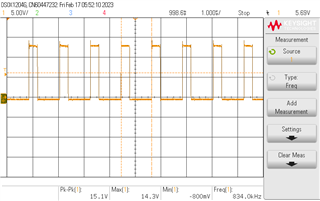

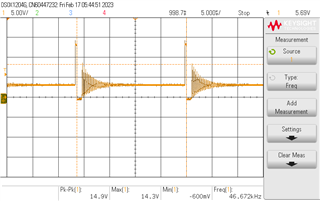

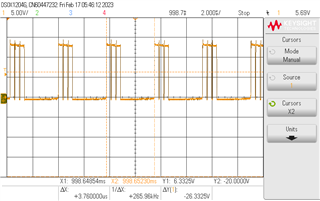

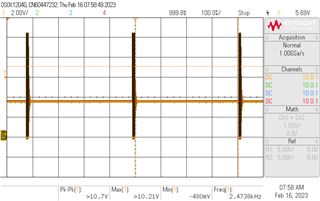

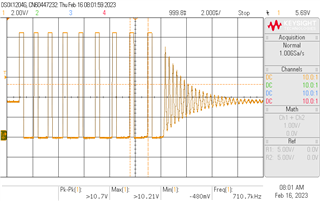

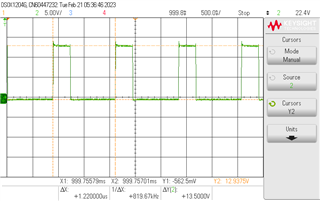

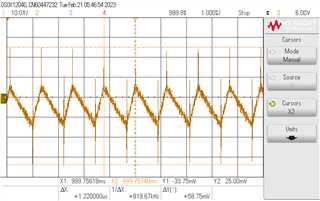

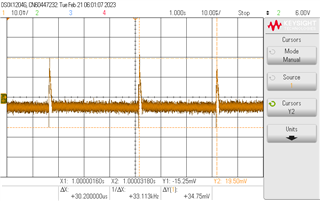

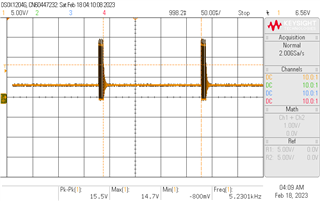

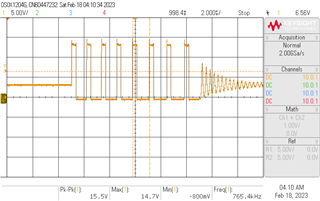

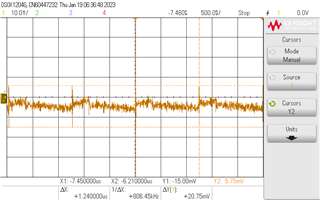

The only questions I have now is about frequency, the frequency calculated with RT = 21 Kohms (1% tolerance) and tD = 64.8 ns (50 ns + 14.8 ns) is around 726 KHz but we are measuring around 806 KHz (image attached).

We are using the MOSFET CPH6355. I understand due to resistor tolerance (RT) & turn on & turn off delay times (typical or maximum), frequency can change a little bit, but I am making calculus and I don't get more than 760 KHz.

So, what can be affecting the frequency? and this difference between frequency measured and frequency calculated, can be considered as the DC-DC converter is not working properly?

If you need more information, more graphs please let me know.

Thanks, and regards.