Other Parts Discussed in Thread: TPS769-Q1

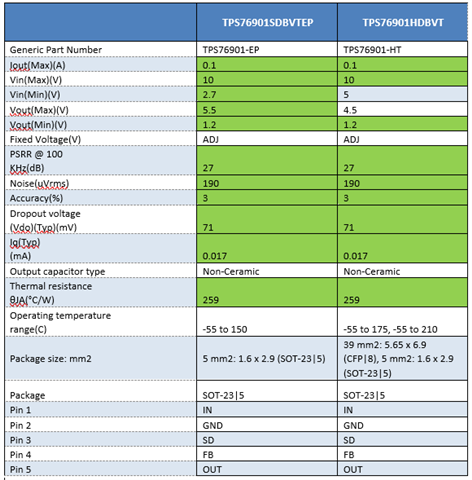

I wanted to inquire about the reliability testing of TPS76901SDBVTEP vs. TPS76901HDBVT. The HT part was recently placed into EOL without chance to LTB. What is the difference in the EP part materials and package or is it just the tests being run for the EP series vs. the HT part? Is the part the same die used in the other TPS76901 LDOs? All the automotive grade parts have thermal shutdowns, and we needed the HT part for tool operation. The 210C parts in the same series are not drop-in replacements and are fairly costly. If the EP series part is just a repackaged HT part, then we are good.

As a side note, do you know why TPS76901HDBVT was obsoleted without any chances to do a life time buy or last time buy?