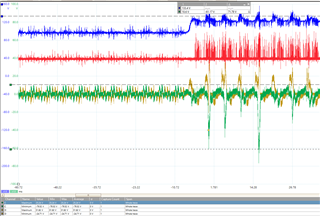

I am working on the current control of a BLDC motor with a speed of 12000rpm. The current controller in the system is designed as PI. I give a reference value of 10A to control the motor and the current controller can follow this reference value within a certain tolerance. When I apply a -10A reference to the BLDC motor, I apply a hard braking and the voltage value feeding the motor increases due to the reverse EMF. I try to burn this rising voltage on the load resistors. However, although I give -10A reference, the instantaneous current value passing through the motor phases rises up to 70-80A levels, and this rising current value damages my mosfets that provide commutation. Can you help me for the problem and solution suggestion here? (I share the Picoscope views with you. The blue signal is the power supply that feeds the motor, the red signal is the mosfet trigger signal that I switch to burn the back emf in the load resistors, the green signal is the current passing through the A phase of the motor and the yellow signal is the current passing through the B phase of the motor)