Other Parts Discussed in Thread: BQSTUDIO, GPCCHEM

Hi TI Team,

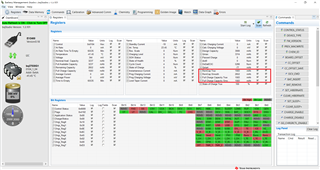

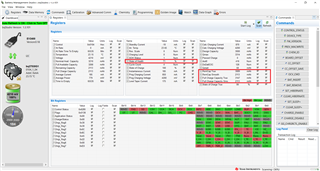

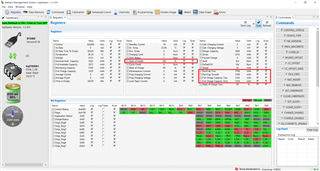

We have successfully completed learning cycle in BQSTUDIO for BQ27530 part with respect to our battery(3000mAH)

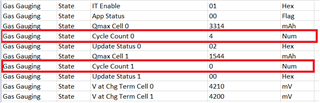

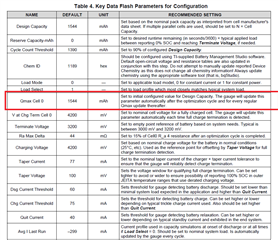

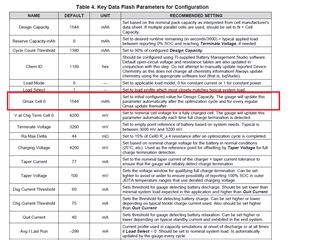

We are facing issue in Full charge Capacity Smooth update, sometimes it is updating properly as ~3000mAH whereas not always.

Full charge capacity Smooth is updated as ~2000mAH which result in SOH dip and battery percentage is also not predicting properly but Full charge Capacity true is predicting properly always

Please let us know what could be the reason for this issue and also attaching .gg file for your reference

Warm Regards,

Mythili B