Hello everyone,

I'm a beginner in electronics design and I'm reaching out to this community for a bit of guidance and advice from those of you with more experience.

I'm working on a project that involves monitoring the temperature of hot surfaces (from appr. 130°C to 190°C) and transmitting this data wirelessly.

I plan to use a STM32 microcontroller paired with an NRF24L01 for the wireless module.

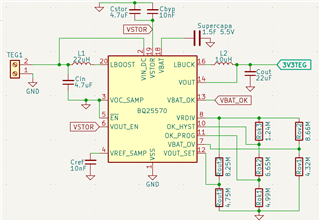

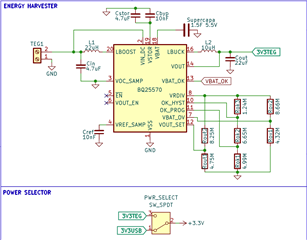

To power this setup, I've designed a schematic based on the BQ25570, incorporating a supercapacitor and a Thermoelectric Generator (TEG). The design closely follows the example given on page 28 of the BQ25570 datasheet.

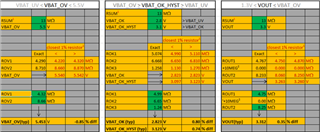

I've chosen the capacitors and inductors based on recommendations from datasheet, and I've calculated the values for the resistors controlling the nano-power management using the dedicated Excel tool :

I'm seeking feedback on a few specific areas of my design and would greatly appreciate any insights you could offer:

- Could you review my schematic for any potential errors?

- I'm unsure about how to determine the appropriate values for VBAT_OK & VBAT_OK_HYST. I've tentatively set these to 2.8V & 3.1V, inspired by other designs, but I'd love to understand the rationale behind these choices.

- For the supercapacitor, I'm considering a 1.5F 5.5V model, which led me to set VBAT_OV at 5.45V. Does this configuration seem reasonable?

- The datasheet specifies using a "low leakage" Cref. Would a MLCC capacitor like this one [here], be suitable? I know that MLCC have low leakage current but wondering if that's fulfilling the expectation.

- I will have a switch to choose from power sources (USB or TEG), seems to be okay to connect/disconnect the load but please allow me to double check this point.

- Finally, I'm exploring options for a TEG module. I'm currently looking at a 5V TEG module such as that one [link]. Would this be a relevant choice to use with BQ25570?

I'm eager to hear your thoughts and any advice you can offer.

Thank you very much.