- Ask a related questionWhat is a related question?A related question is a question created from another question. When the related question is created, it will be automatically linked to the original question.

This thread has been locked.

If you have a related question, please click the "Ask a related question" button in the top right corner. The newly created question will be automatically linked to this question.

Tool/software:

Dear team,

My customer would like to use UCC28C53 for their application.

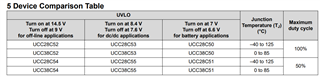

As we can see like below, UCC28C53 with 100% duty and UCC28C55 with 50% max duty.

My customer ask why there is 50% max duty device, Can 100% max duty device cover max 50% duty device?

Which application should have which duty spec device?

Please let me know the pros and cons of using 100% duty device and using 50% duty device.

Thank you.

Hi,

No pros and cons, it depends your design needs more than 50% duty cycle or not. If your design needs max duty cycle not more than 50%, then use a device with max 50% duty cycle can help avoid entering > 50%, which would need to add current slope compensation. But if your design needs max duty cycle > 50%, then you have to use a device with max 100%, then a current slope compensation is required to add in.