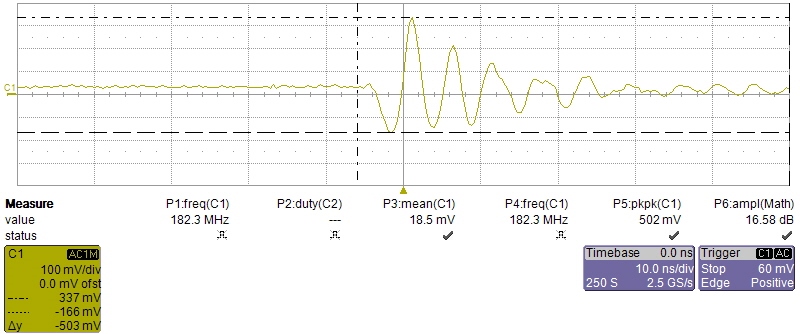

I'm currently using the LM5006 and recently took it in for EMI testing and found that there was a lot of noise around 185MHz. Upon closer investigation, there is ringing at 185MHz at every switching cycle. I see the ringing everywhere (Cin, Cout, etc) so I'm not sure exactly where it's coming from. I have the LM5006 Eval board, and I see the same 185MHz ringing on that board, so it's not due to flaws in my layout (or at least not flaws that aren't shared by the eval board).

Some component values:

Cin is 1uF, 0805 and 0.1uF, 0603.

Cout is 15uF, 1210

Inductor is 82uH.

I am using a diode for the freewheel switch, PMEG6020ER,115

Outside of the ringing the circuit has performed very well (accurate, efficient, etc). I have input and output wires which are probably responsible for the EMI and I'm prepared to use appropriate ferrites to keep the noise from radiating. HOWEVER - it would be great to add an additional capacitor or two and reduce the noise at the source, rather than just relying on the ferrite. Given that the ringing is reproduceable on the eval board, could you (or anyone) recommend any particular tweaks that could help?