Hello,

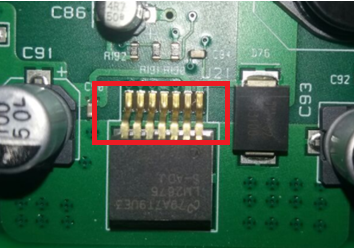

In Feb of this year, we received 100pcs LM2676S-ADJ/NOPB from Mouser. Now, we got customer feedback that this part should have tin plated leads as per data sheet but the actual parts are without plating.the lead color is golden(see attached picture). Pls help to confirm what's the reason for this issue. Now, our customer is waiting reply from us. pls help to give us reply as soon as possible. thanks.

The batch number of these 100pcs is below

1736+5

7389253EM7

1744+5

7439679EM7