A while back I posted a thread about EMC problems with a LM25005 design. (https://e2e.ti.com/support/power-management/f/196/t/737098I believed the issue was solved but it turned out we still had emissions above the allowed thresholds.

I'll try again to upload the schematics, layout and spectrum graph.

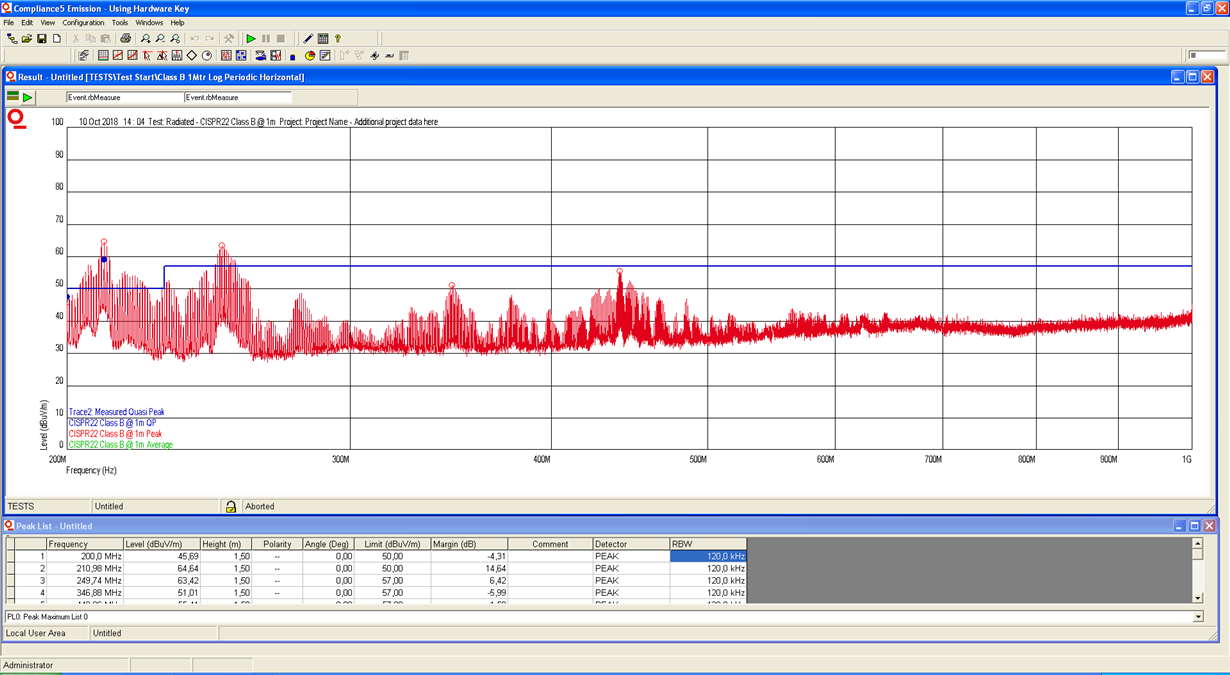

And the emission plot at first EMC-test:

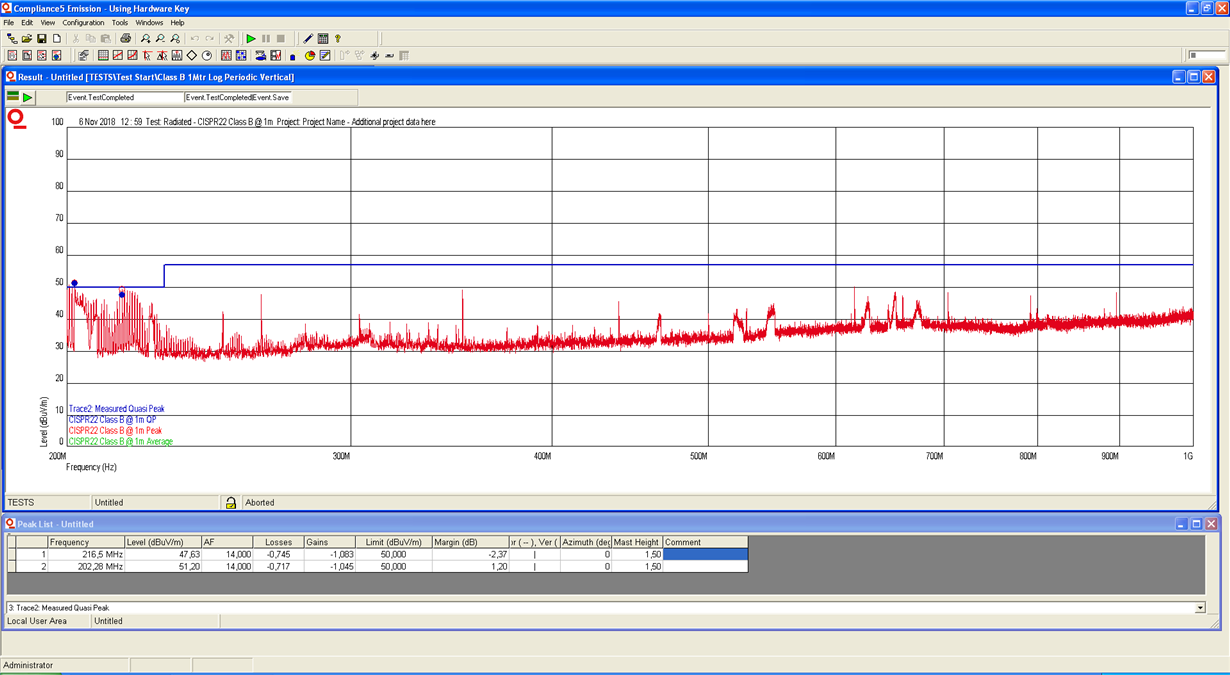

Changing the diode to B370-13-F moved the noise down in frequency, but it is still too much.

In addition to changing the diode I also added a snubber network as per the datasheet. That helped, but still not enough. I even put a small resistance in series with the boost capacitor to slow down the transitions. The difference was measurable but not great.

We have identified a few areas in the layout that could improve, such as:

-Better separation between planes to decrease capacitance

-Bteeter routing of the feedback signals.

-Better mounting of the diode and snubber. Since they where retrofitted they are squeezed in as well as they could be.

I'm very thankful for any input!

Best regards,

Andreas Wileur