Other Parts Discussed in Thread: TPS62363, TMP103, PCA9306

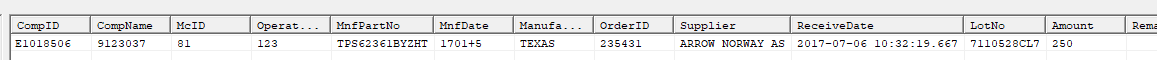

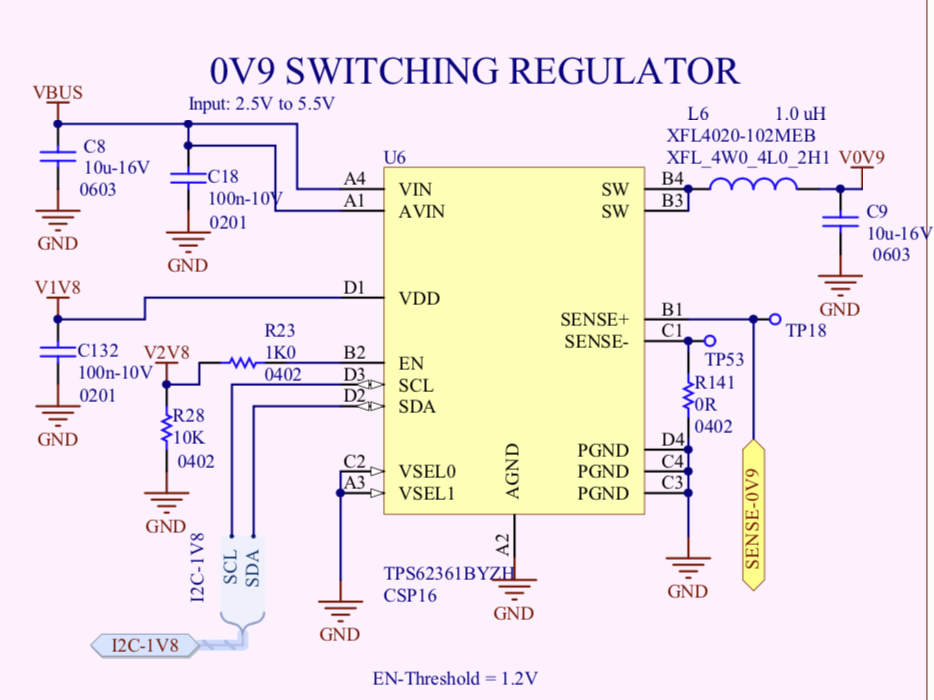

We have a design where the TPS62361B is being used to generate a 0V9 digital core voltage. We’ve seen on two different samples of the same board that the voltage output is ~1.2V instead of 0.9V, which of course is not good.

VSEL0 / VSEL1 are both grounded, and the value in the SET0 register is 0x28.

With the TPS62361B, this should give 0.9V out.

With the TPS62363, the output for the same register value would be 1.17V.

Changing the SET0 register to 0x0D changes the output voltage to 0.9V, which indicates that the internal reference voltage is 770mV, not 500mV.

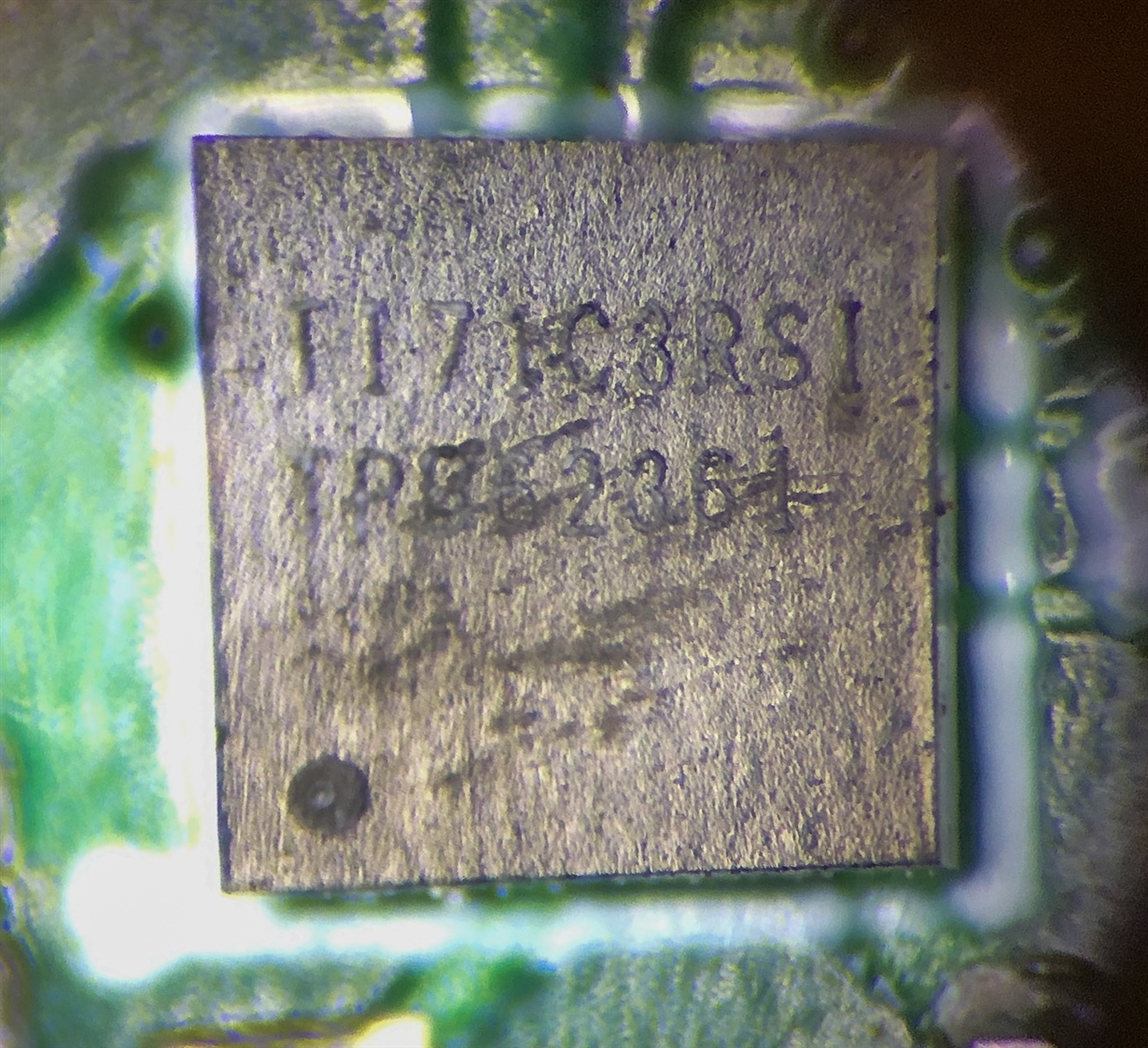

The Chip ID register gives 0x87, which identifies the chip as the TPS62361B, and the markings on the top of the package also supports this.

Is there anything that could make a TPS62361B behave like the TPS62363?

This is really puzzling us at the moment. Any pointers as to how this could happen would be very much appreciated.