Other Parts Discussed in Thread: LM317

The operation condition is 15Vin and 5Vout with 100mA in motor drive application.

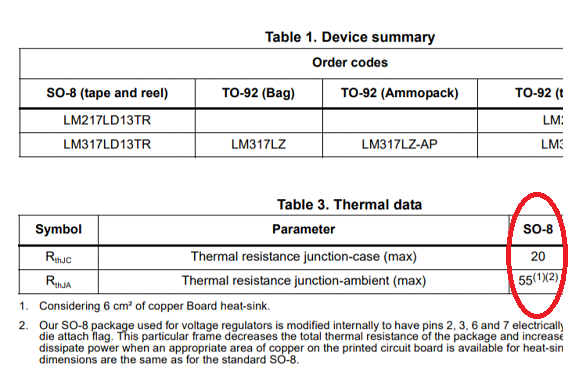

We found there is a similar part from STM, LM317LD13TR. in which, the thermal resistance is much lower for SO8 package. Is it true?

In the LM317L, the Theta_JA is about 97degree/W much higher than 55degree/W of the LM317LD13TR, correct?

Thermal is a critical parameter in this design. Is there any p2p compatible device with LM317LD13TR in this application? Thanks.

Regards

Brian