- Ask a related questionWhat is a related question?A related question is a question created from another question. When the related question is created, it will be automatically linked to the original question.

This thread has been locked.

If you have a related question, please click the "Ask a related question" button in the top right corner. The newly created question will be automatically linked to this question.

Hi,

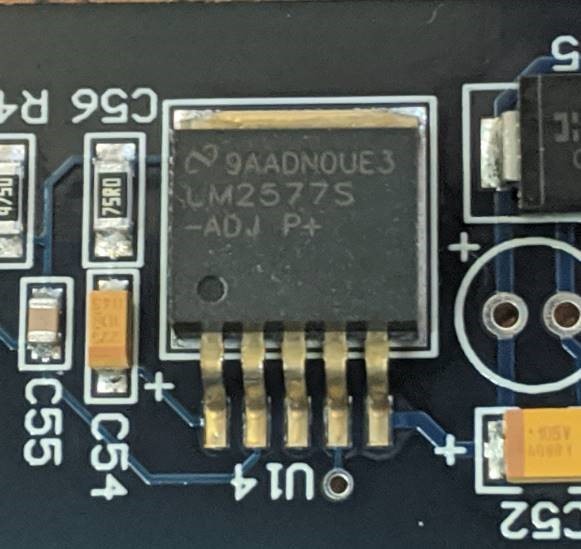

We are noticing a discoloration of the exposed metal only on this particular part after Reflow soldering.

This is evident in the picture below when comparing the lead color to that of other components.

There is no issue with the solder wetting to the component leads.

We have confirmed that the peak temperature reached during reflow is 224c.

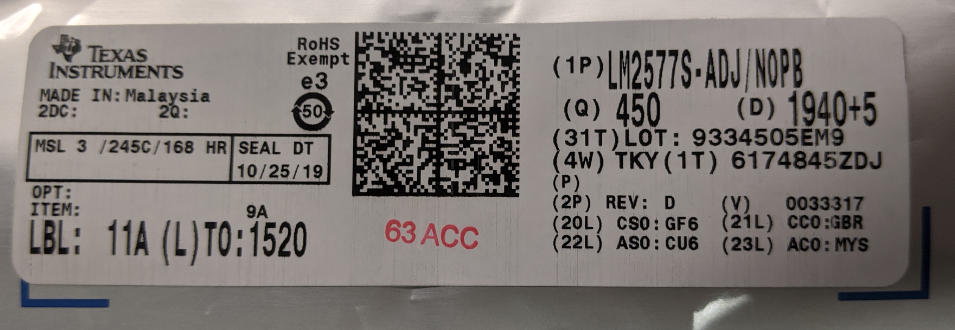

First we want to make sure that the actual component markings on the parts properly correlate to the different part number markings on the bag label and that we do have the correct parts and that they are RoHS.

Second we would like to know if we need to be concerned about the discoloration or can ignore it?

We are using a lead free SAC305 water soluble flux type solder paste.

Hi Alan,

Let me talk to our product engineer and I will get back to you.

Thanks,

Richard

Hi Alan,

Just wanted to let you know that we're still working on this.

Thank you for your patience,

Richard

Hi Alan,

Apologies for the delay.

The top marking on that part matches the internal database and shipping label.

Unfortunately, the part is RoHS-exempt because it uses lead solder on the die-attach, which gives this part better electrical/thermal conductivity. If you need RoHS, you will need LM2775M-ADJ.

Discoloration appears to be normal, it is possible to be gold-plated.

Thanks,

Richard