Other Parts Discussed in Thread: GPCCHEM, BQSTUDIO,

Hi TI Team,

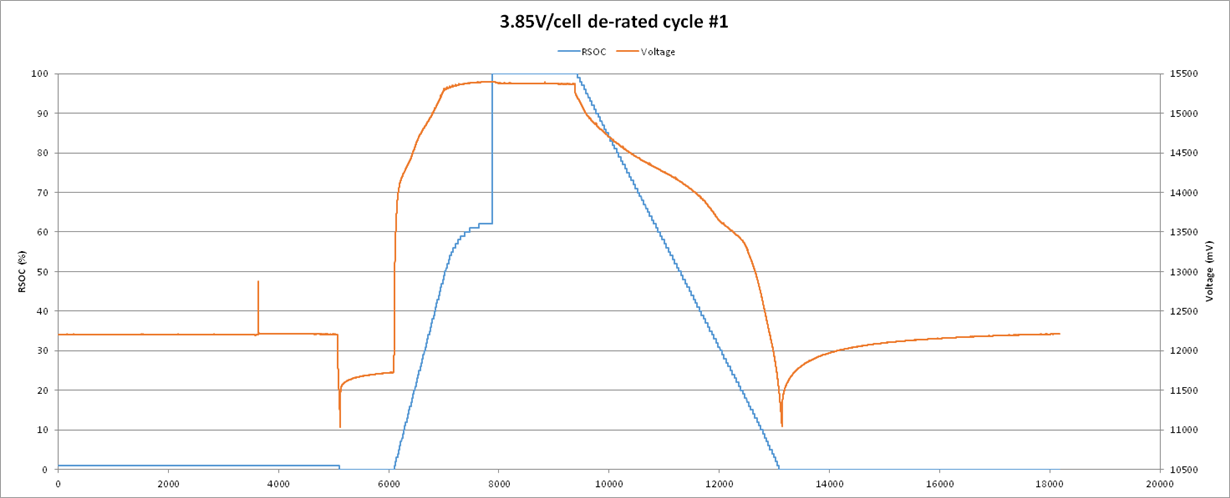

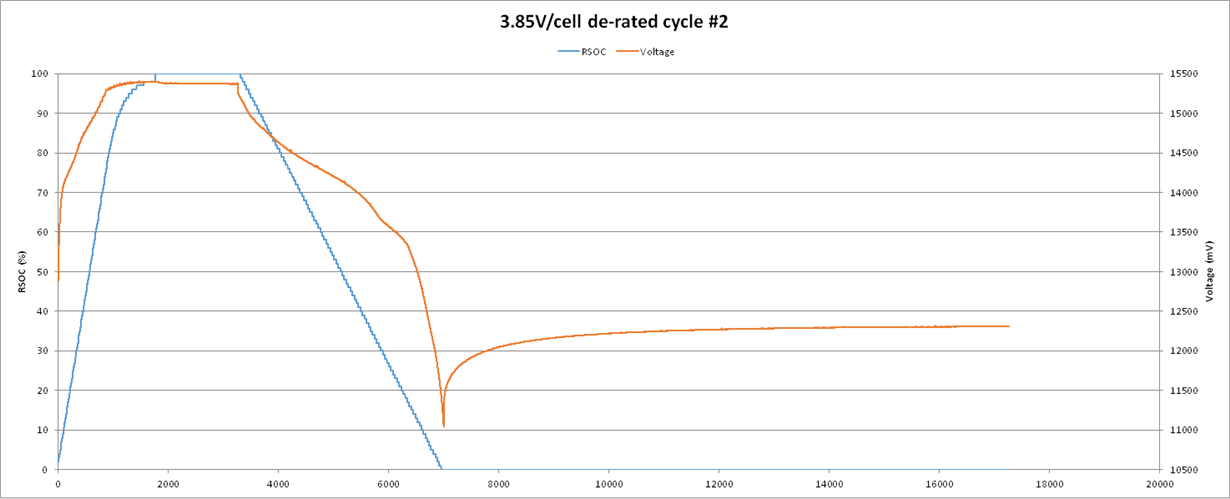

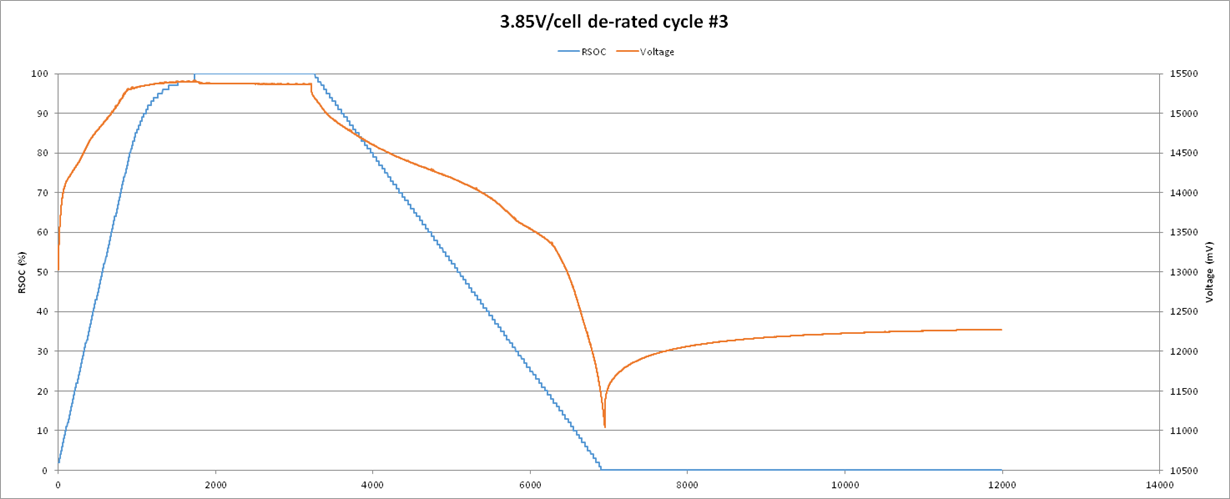

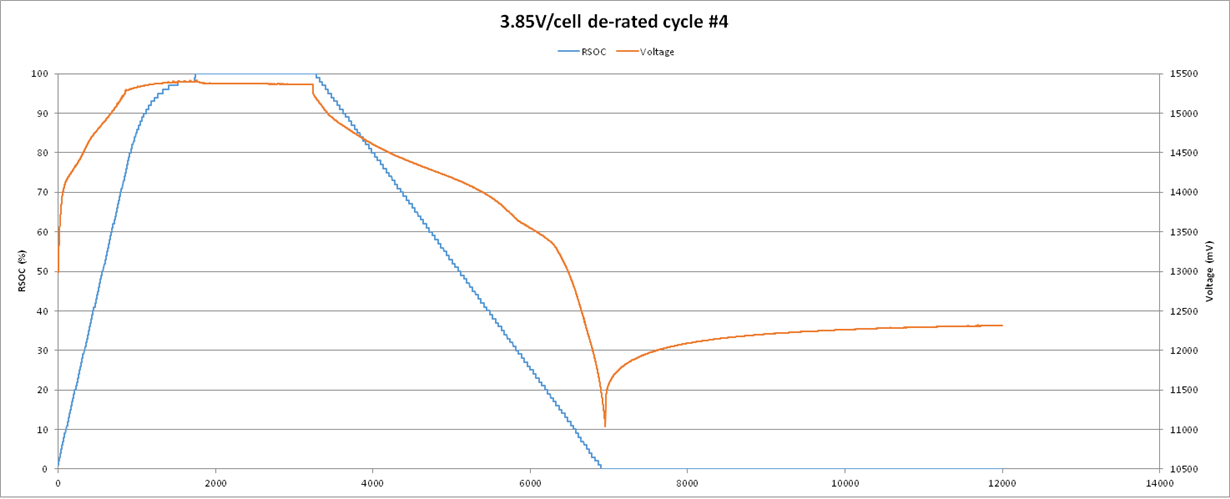

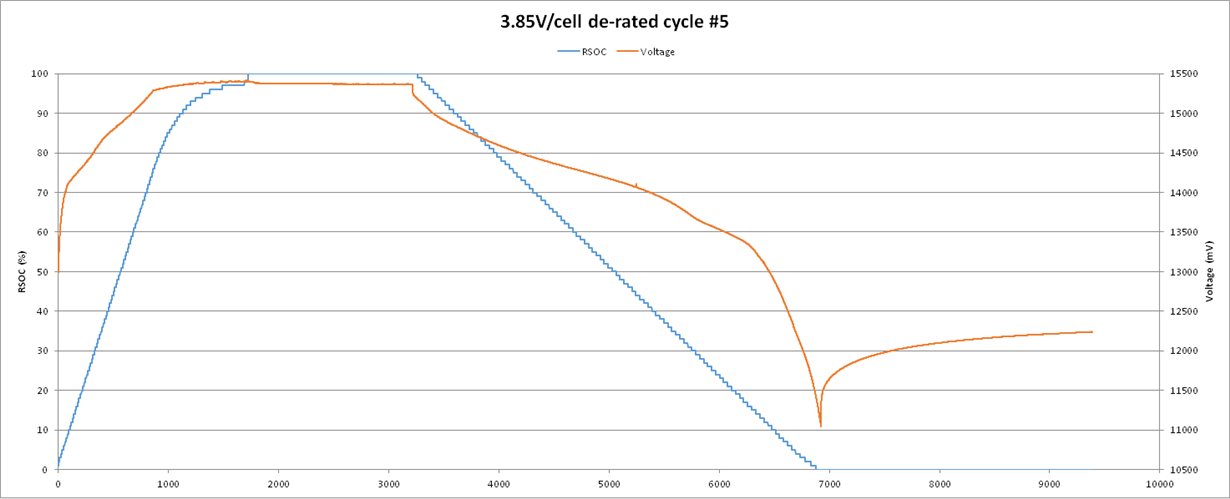

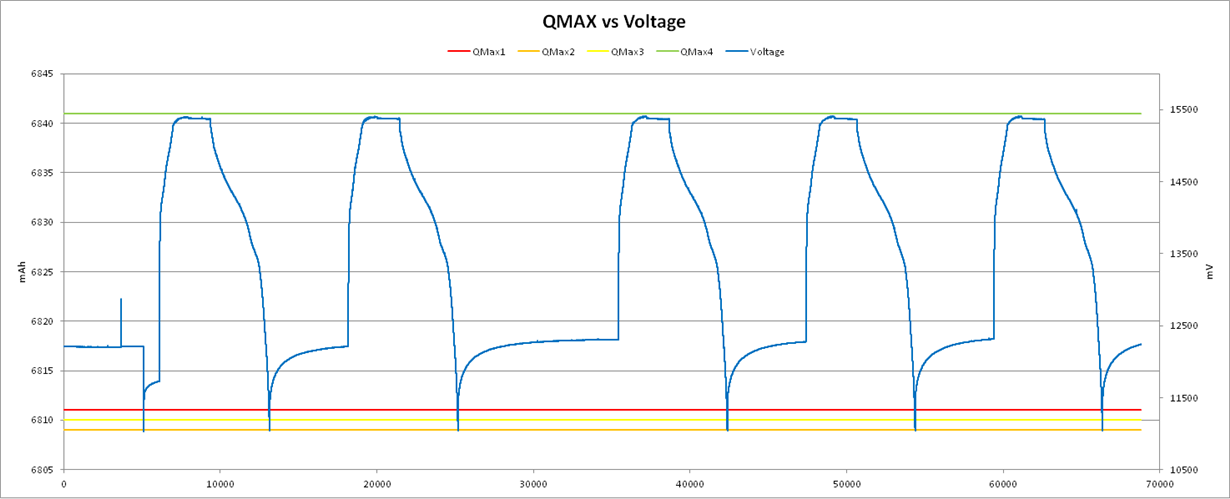

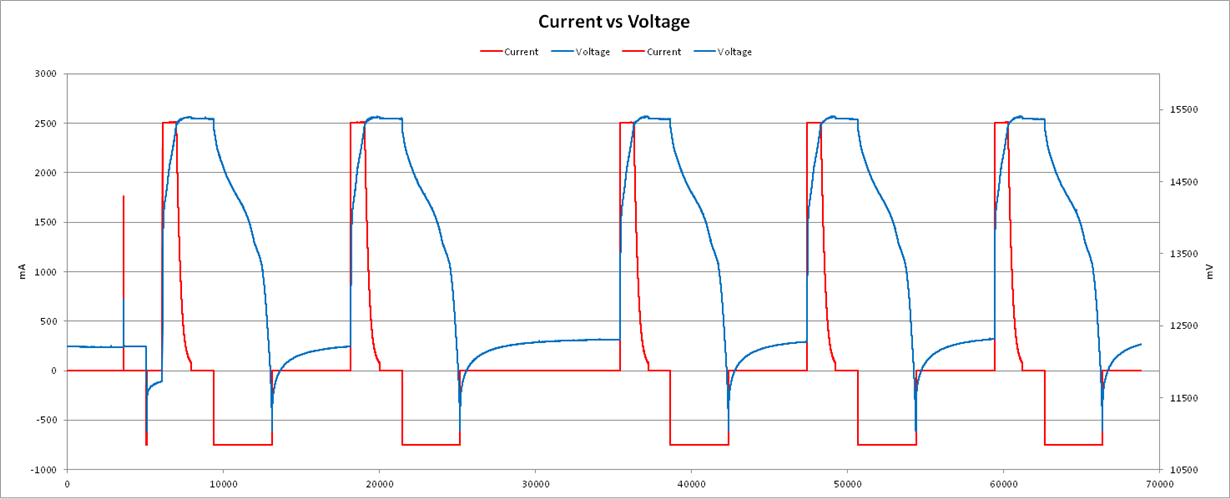

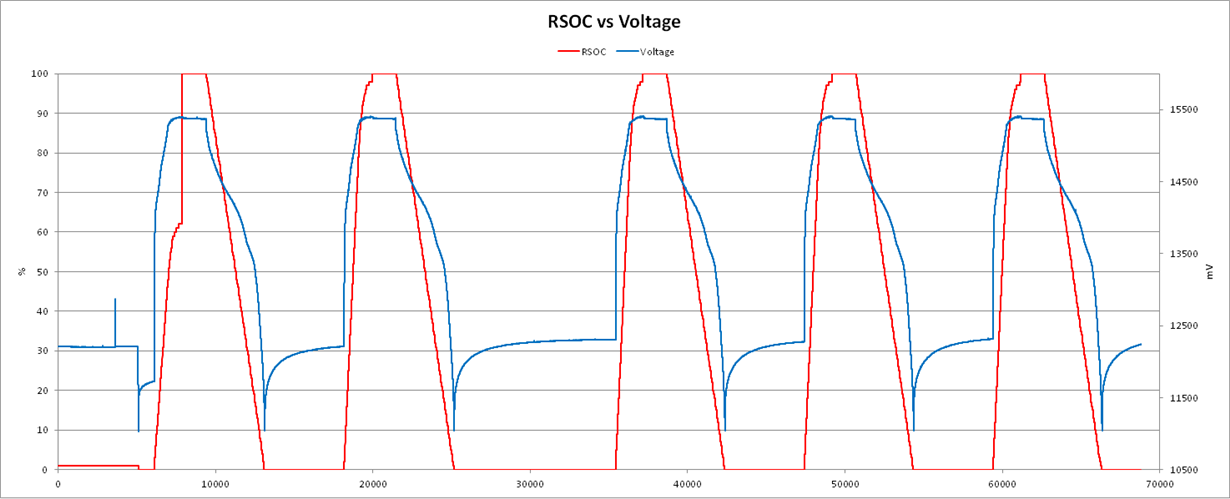

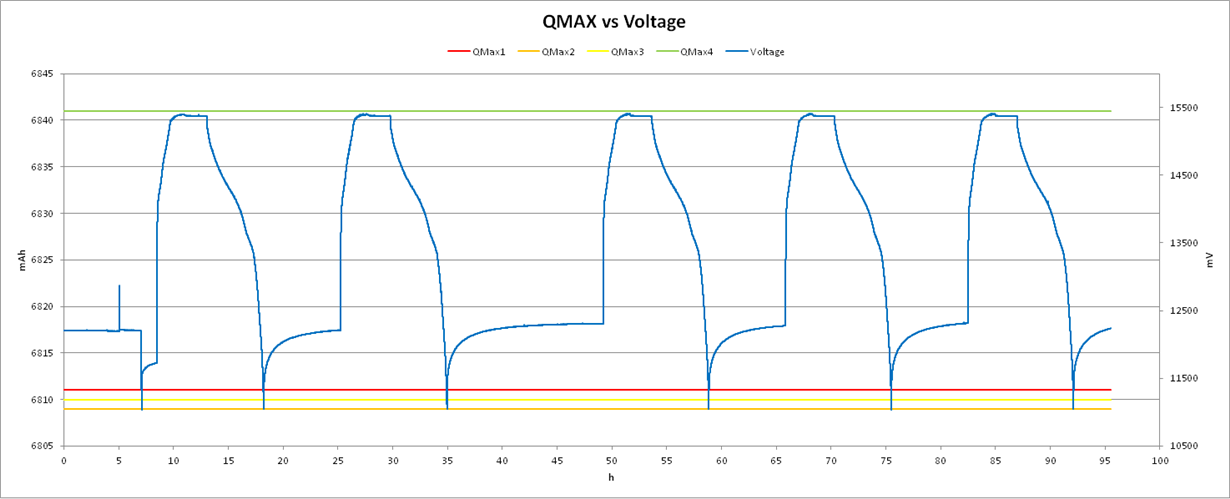

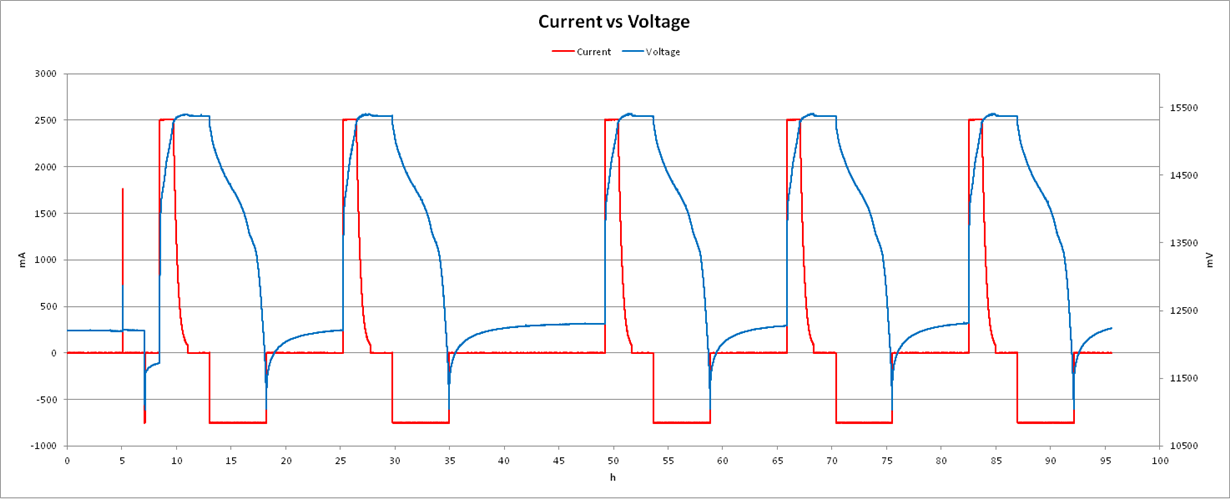

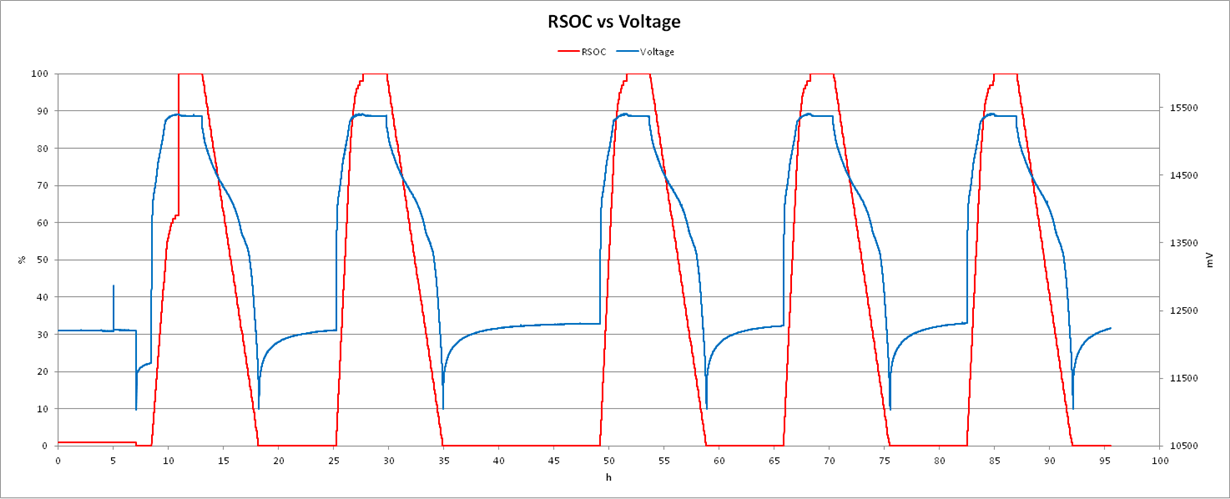

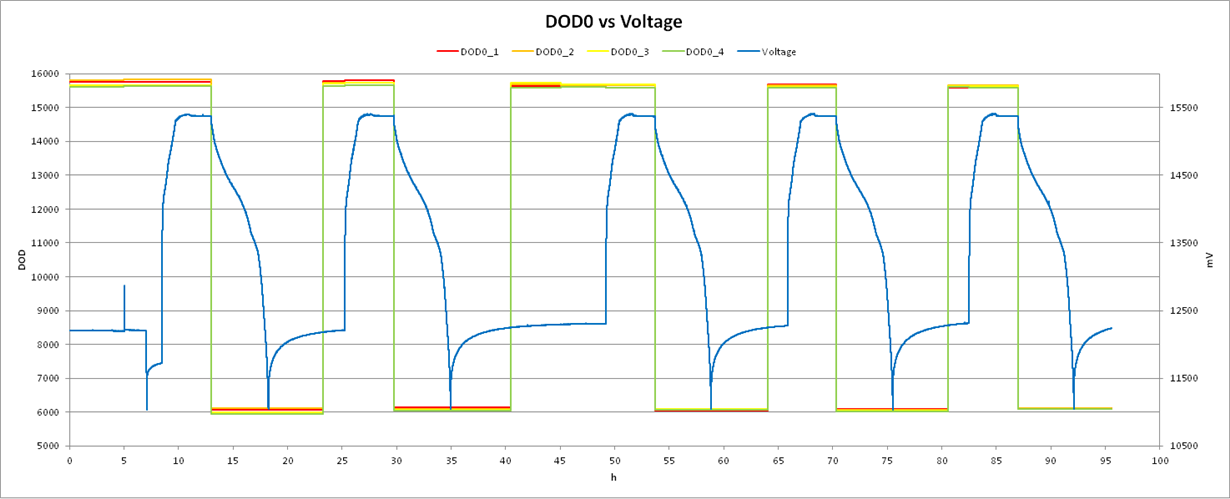

I have an application that requires charging voltage de-rated to 3.85V/cell. I tried to perform a learning cycle, but seems QMAX were not updated and FCC is updated about 1000mAh down to actual measured capacity. Can you please advise what to do for this case?

Also attached initial DF before learning cycle, last DF after learning cycle, and log data during learning cycle.

Thanks,