Other Parts Discussed in Thread: UCC27511,

Hello everyone,

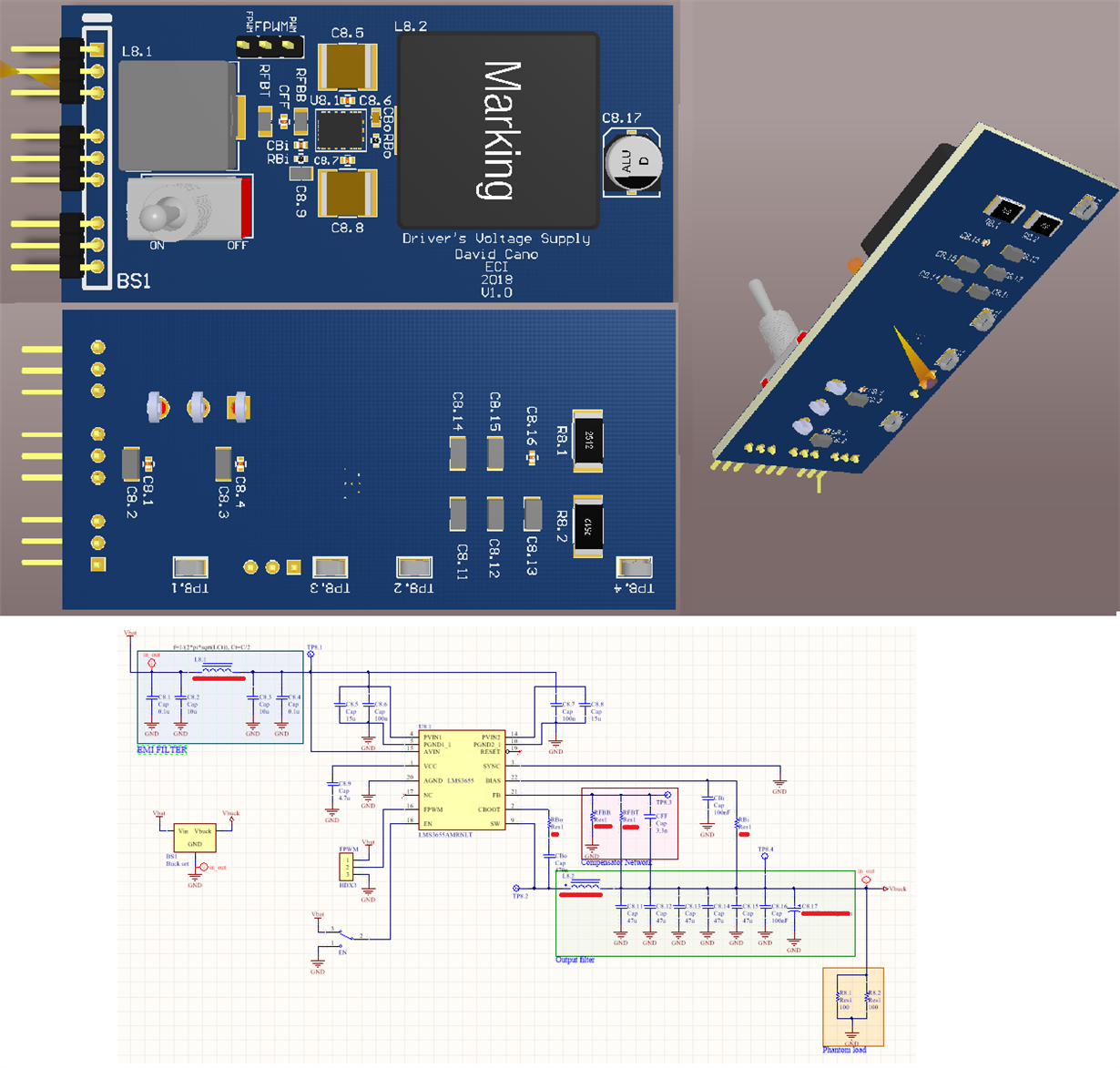

I am using the LMS3655AMRNLT synchronous Buck converter to step down 24 V to 12 V. The schematic and PCB design are almost done. The last one was made following the indicated recomendations of it datasheet (http://www.ti.com/lit/ds/symlink/lms3655-q1.pdf ). On page 42 it is said (see highlited text):

As i get it, It seems that those layers require that amount of copper so that the heat dissipation could be possible. My question is: what if i use 1-oz copper top and bottom layer instead of 2-oz, but I make up for with a heat sink placed right behind the chip -see the arrow of the right image- (of course, following the other recomendations, specially the "huge" top and bottom ground polygon)? would the convert work properly?

FInally, I want to add that the size of that module is about 75mm x 35 mm.

TI team or reader, as always, thank you for your help.

Any further comments would be appreciated.

Best regards,

David Cano.