Other Parts Discussed in Thread: TPS546D24A, TPS546D24

Hi there,

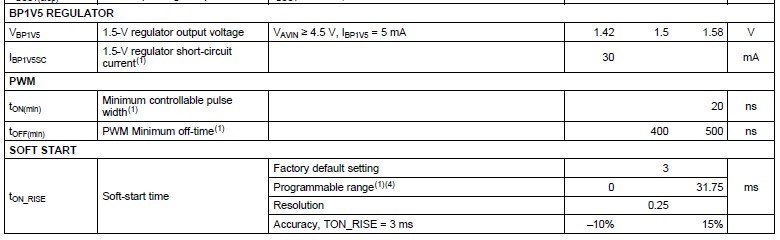

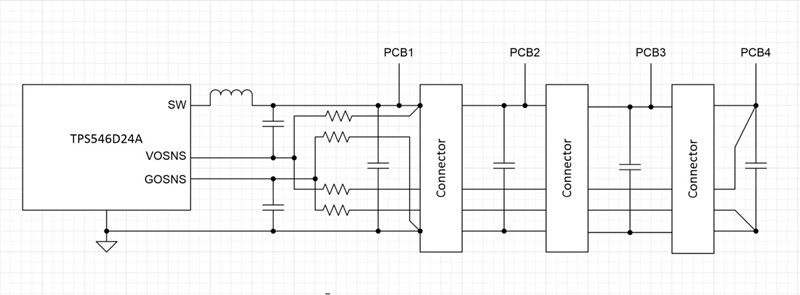

Does TPS546D24AEVM board could output a voltage higher than 1.5V? The inductor value on EVM board is 150nH, Does the Output support 0.6 V to 5.5 V at 80 A?

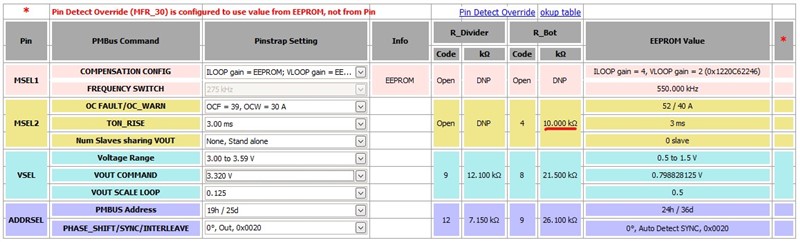

When I set the output voltage using Fusion Digital Power Designer. There have a note: You must enter a number betweent 0 to 1.5.

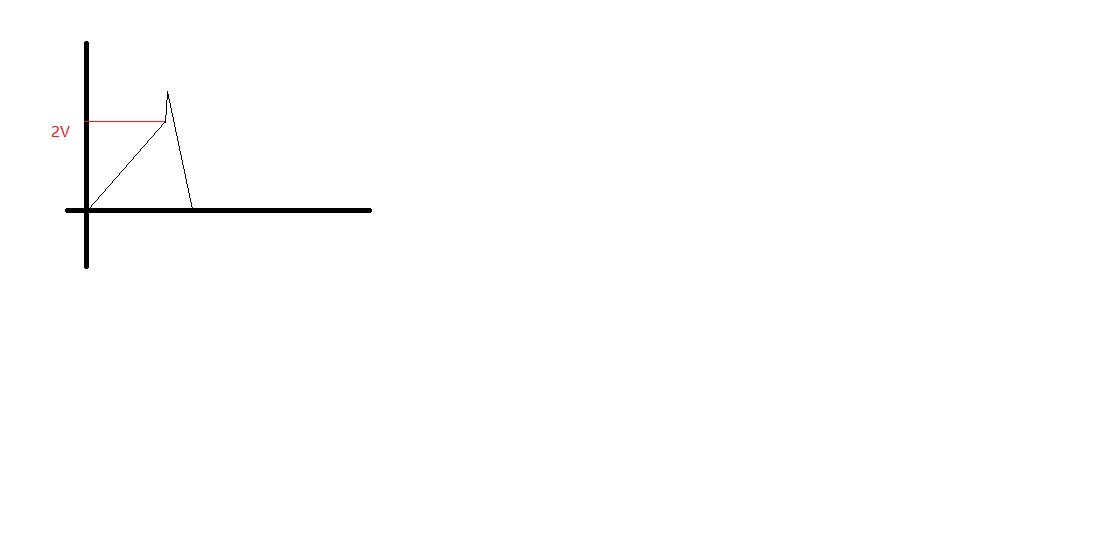

I changed the Pin Strapping. But there was nothing happend. How to set these commond to EEPROM?

Here is Pin Strapping.

Pin_detect_override is set to 0x1F2F.

Regards,

Ricardo