Other Parts Discussed in Thread: AM62P, SYSCONFIG, AM62P5-Q1

Tool/software:

Hi TI Experts,

Is there a list of design recommendations or commonly observed errors for SD card Interface during Custom board hardware design?

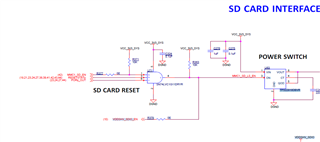

Below are some common queries i have

1. Pullup recommendations

2. Power supply and Sequencing

3. Series resistor for SD card clock output from the processor

4. Power switch for SD card reset