Other Parts Discussed in Thread: BOOSTXL-TUSS4470, TUSS4470

Hello,

I hope you are well.

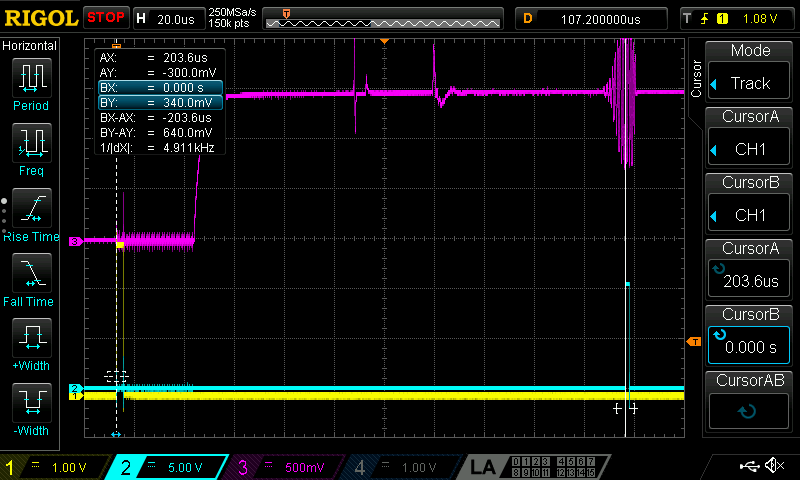

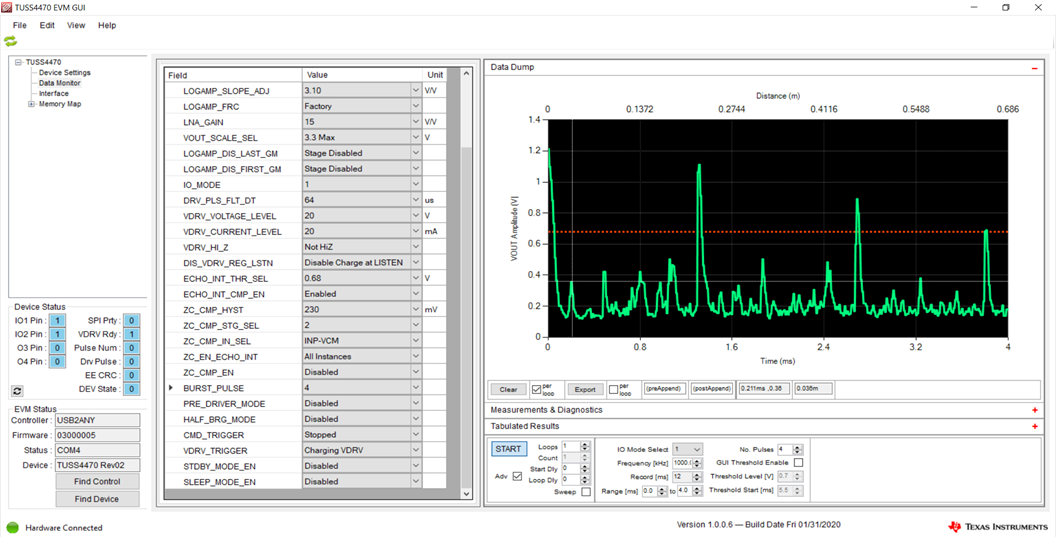

I have designed the TDC1000 in one of our prototypes and so far we were able to prove the functionality, through the bottom of a plastic tank. We successfully get both the start and stop pulses, and when measuring on the scope, the TOF is correct.

We then applied the same prototype and sensor configuration, to the bottom of a metal tank but unfortunately, did not get any useful results.

We followed several of the examples online/in the forum, including the "How to perform liquid level sensing through the bottom of a metal tank" tutorial. It'd be great to hear if you have any more ideas of us to try and test?

Just as a note, we have a 30V rail that's permanently connected to the transducer, which I suppose could be part of the issue.

Thank you.