Other Parts Discussed in Thread: AMC1300, DRV425

Measuring +-300amp current from a welding machine, can TMCS1100 be used in parallel to meet this range?

This thread has been locked.

If you have a related question, please click the "Ask a related question" button in the top right corner. The newly created question will be automatically linked to this question.

Andrew,

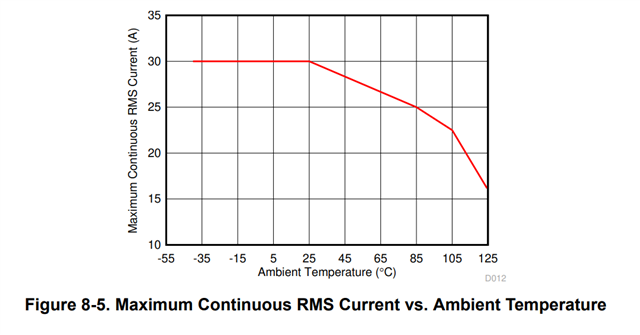

Unfortunately this is far too much current to pass through such a device. Allowable current in the TMCS110x family is constrained by self-heating due to power dissipation in the input conductor, and we generate a SOA curve for allowable current to be passed through the device. Even in optimal temperature conditions, you can see from the curve below that this value is maximized 30A, well under the 300A requirement you're looking for:

Currents of this magnitude passed through the device would actually result in fusing of the lead frame, and therefore IC failure.

Normally for this level of current measurement, we recommend entirely passive solutions such as the DRV425 fluxgate sensor, where ambient field is measured by the device externally, without passing this magnitude of current through the IC. While challenging to design, shunt based solutions may also be employed here, with shunts typically measuring in the micro-ohms for these types of applications. If you need isolation in the IC similar to the TMCS family, I would recommend looking at the AMC1300 family for this type of solution.

I understand that this would be too much current for a single device, Can they be used in Parallel, for example 10 TMCS1100 in parallel to meet this amperage range?

Andrew,

While, in theory, yes this should be possible, we have not investigated such a solution, and do not have any collateral I can share for such a design. There are several challenges/pitfalls to such a solution you would need to pay attention to:

1. As shown in the above curve, the ambient temperature would need to be held to a value less than typical room for this amount of continuous RMS current flow. I don't know how realistic this is, and most likely, you would need more than 10 devices to reach a 300A current limit.

2. Note that the leadframe resistance of 1.8mΩ is a typical value, and there will be variation in the leadframe resistance from device to device. This means that there will be non-uniformity in the current legs, and you may run into accuracy issues dependent on how you choose to measure the overall output current of the system.

3. In addition to the above, there is a published spec in the datasheet showing an increasing resistance due to temperature drift. This could further exacerbate the above issue if temperature gradient is different across the board (i.e., some TMCS devices are hotter than others during operation).

4. As each device requires its own individual input current, routing the input traces during the layout of this many devices in parallel seems like a challenge from a thermal/angle of approach perspective (section 12 of he datasheet).