Hello,

For an application, I am looking for an adequate ADC and I would like to know which parameters I should consider and how I should interpret them to calculate the final error. I am measuring an NTC which full range voltage ranges from 65mV to 85mV and I have to detect changes of 20uV. This means that the final error in the ADC, after offset, gain error, noise etc cannot be higher than 20uV*Gain. I was thiniking about using a Wheatstone bridge (to "extract" the 20mV difference), and amplify and read this difference by using a sigma-delta ADC with gain (at least of 8 or higher) and 18 to 24bits resolution. Could you give me some guidance for the correct selection of the ADC or a model suggestion? I'm also a bit confused in the part of calculating the overall error. For example, if the offset of an ADC model is 30uV (higher than the 20uV maximum error), then should I discard this model? For instance, ADS8887IDRCT offset, according to datasheet, is up to 4mV.

I hope you can help me in that.

Best regards,

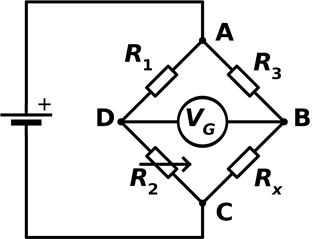

so that Vdd is REF7012QFKHT, with 1.25V output, 0.025% accuracy and 2ppm/ºC. R1 and R3, 20K, 0.01%, 10ppm/ºC, RX would be the NTC and R4 would be 1K 0.01% resistor.

so that Vdd is REF7012QFKHT, with 1.25V output, 0.025% accuracy and 2ppm/ºC. R1 and R3, 20K, 0.01%, 10ppm/ºC, RX would be the NTC and R4 would be 1K 0.01% resistor.