Other Parts Discussed in Thread: LDC1614

Hi TI team,

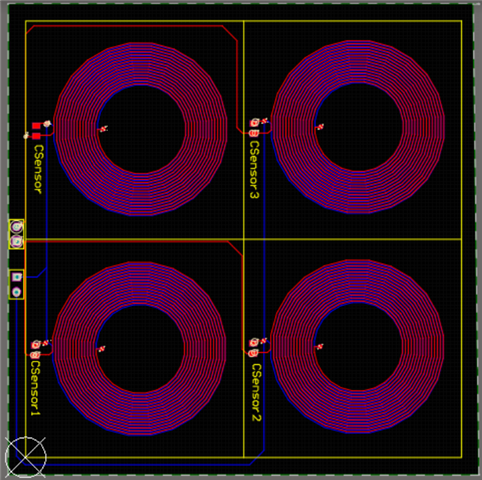

I am working on one product design where we need to identify four different objects on a 2x2 coil array (similar to the keypad design). I explored and found that this can be achieved with inductive sensing and the LDC series is the right choice for this application.

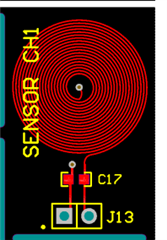

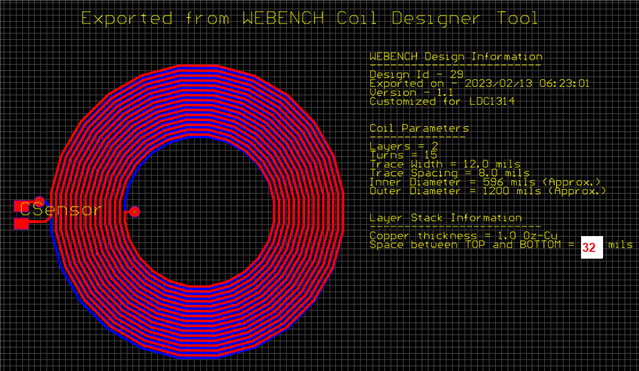

I started with the LDC1614EVK and my custom-design coil. I designed the coil from the coil design tool on the TI website. Following is the 2x2 coil array with coil details.

With this I am facing the following issues:

- I connect only a single coil on CH0 and it is detecting perfectly on the Sensing EVK GUI and no variation in inductance in GUI data.

- When I connect the 2x2 array on CH0 and CH1, inductance starts getting vary and not stable on the GUI data. It has a huge variation. Can you please let me know how can I make it stable?

- Also, my application is to detect 4 different objects, so I am planning to use different wire Inductor values inside the object i.e. 100uH, 200uH, and 300uH, etc. My object and coil distance is less than 10mm. Due to variations in the inductance of the, I am not able to detect changes of inductance when I place an object on the coil.

Can you please guide me on how to make 2x2 array coil inductance stable? Also, with different inductor value, Can I able to differentiate the objects?

Total PCB thickness=0.8mm and FR4 material.

Looking forward to your valuable feedback to solve the issue.

Thanks,

Hitesh