Hello E2E Experts,

Good day.

We are in the late stage of the development of a Residual Current Monitoring device (IEC62752 compliant) using the DRV421 IC. Recently, we performed high-low temperature tests on the device and discovered that the offset drift over temperature is quite high. It seems like the offset drift comes from the DRV421 having drift largely exceeding what was stated in the datasheet. This was found by measuring the voltage across RSHUNT over -30C ~ 60C, which is the shunt resistor in series with the compensation coil. Following is test results:

Test conditions: Zero primary currents, compensation coil 100 turns, RSHUNT = 100 ohms, nanocrystalline core (shape and dimensions in attachment core.pdf)

Test performed in the temperature chamber

| Temperature C | RSHUNT(mV) |

| -30 | 6.5 |

| -25 | 6.2 |

| -20 | 6.05 |

| -15 | 5.99 |

| -10 | 7.5 |

| -5 | 5.44 |

| 0 | 4.9 |

| 5 | 4.6 |

| 10 | 4.11 |

| 15 | 3.8 |

| 20 | 2.9 |

| 25 | 2.2 |

| 30 | 1.7 |

| 35 | 1.2 |

| 40 | 0.5 |

| 45 | -0.2 |

| 50 | -0.8 |

| 55 | -0.8 |

| 60 | -1.02 |

As can be seen, the initial offset in mV (at 25 deg C) is around 2.2, which should correspond to the max. 8µT, typ.~1µT initial offset in magnetic flux density. But at 5 deg C, with only 20 deg C difference in temperature from 25 deg C, the change in offset is already 4.6mV -2.2mV = 2.4 mV, exceeding the initial offset. On the datasheet, typ. 5nT/°C is stated as offset drift. According to this information, a change in offset due to 20 deg C change in temperature should be around 10% of the initial offset in a typical case. (typ. 1µT initial offset / (5nT/°C * 20°C ) = 0.1)

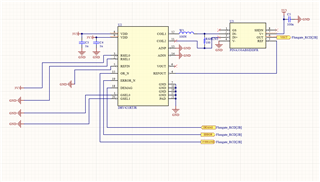

Relevant schematic:

Could you advise on what could be the cause to this high offset drift, and what could be done to mitigate it? Thank you very much in advance!

Regards,

CSC