Other Parts Discussed in Thread: DRV5023

Hi Team,

We have one urgent case from customer side when using DRV5023AJQDBZRQ1 for magnet distance on/off detection. After -40C low temperature aging test for their product and recover to room temperature, the DRV5023 output is always keeping HIGH no matter the magnet is near by or far away. But after powering off and on again for DRV5023 VCC, it will output LOW with magnet nearby correctly. Then remove magnet and put it nearby again, it still keeps HIGH for the output, only by toggling the VCC can reset it one time for correct output behavior.

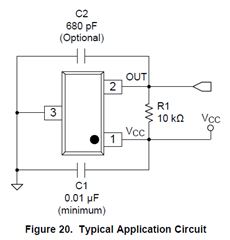

Customer is following datasheet schematic as below and VCC=5V, please help to check what's the possible reason for this failure behavior as your earlier as possible.

Thanks a lot!