Other Parts Discussed in Thread: TMAG5173EVM

Tool/software:

Hi,

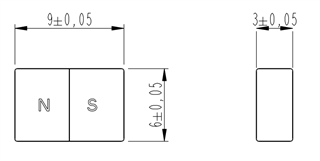

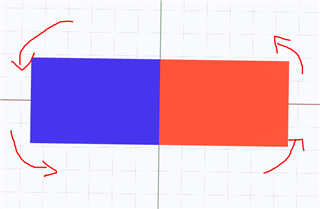

I am using this sensor for angle measurement in rotary application for XY.

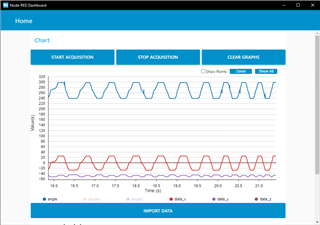

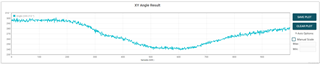

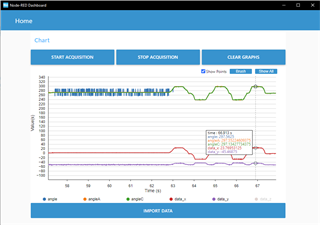

I am using example code. I am getting weird result for angle like in these pictures.

angle: Sensor angle results

angleA: calculated with atan2f(By,Bx)

angleC: calculated calcCORDIC()

All angle results are matching. Mechanical angle is ±30 degree.

For some mechanical angles there is deflection in angle results. I have changed mechanics, but it still has deflection in random angles and random times.

What can be the problem?

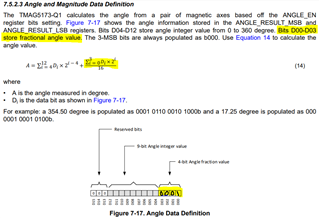

Which magnetic channel setting should I choose for absolute angle calculation?( XY,XYX,YXY or other)

Thanks