Tool/software:

Hi Samhitha,

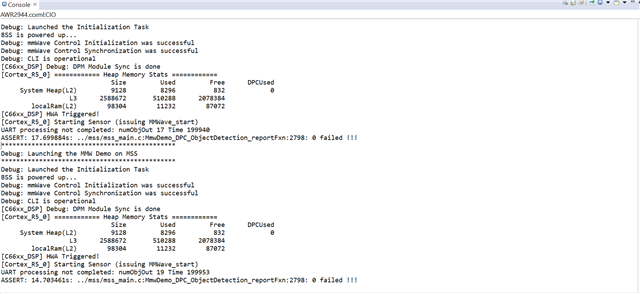

I have tried the OOB data over can project using different version of ccs for example 1220,1240,1260,1270,1271 with SDK version of 4.4.1.2 and radar toolbox version 2.20.0.5, 2.10.0.4, 2.0.0.6, 1.30.1.3 where the error remains the same, I have doubted the installation process what I have done and reset the PC and installed as per the instructions given in api_guide_awr294x, the tried the same process but error remains the same, for hardware connection, I used two different connection for checking.

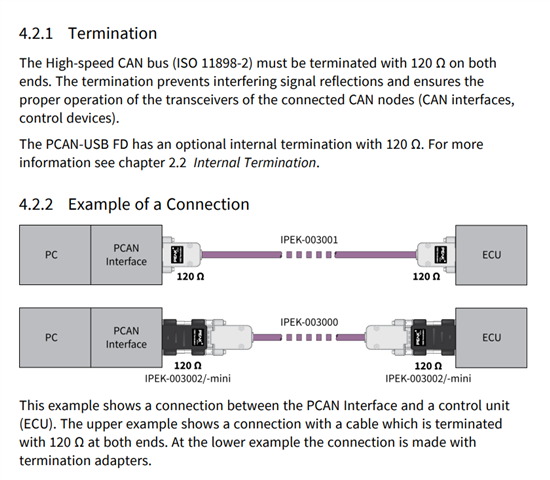

connection - 1:

CANA_H - CANH

CANA_L - CANL

GND - GND

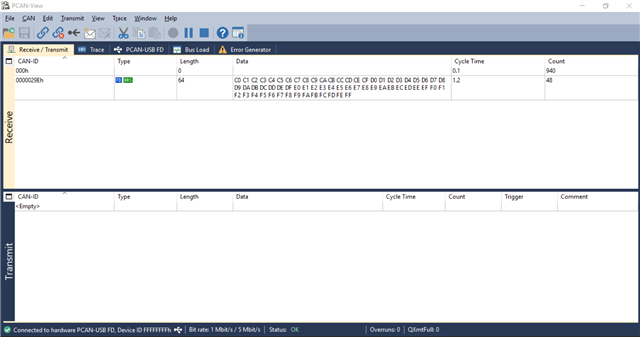

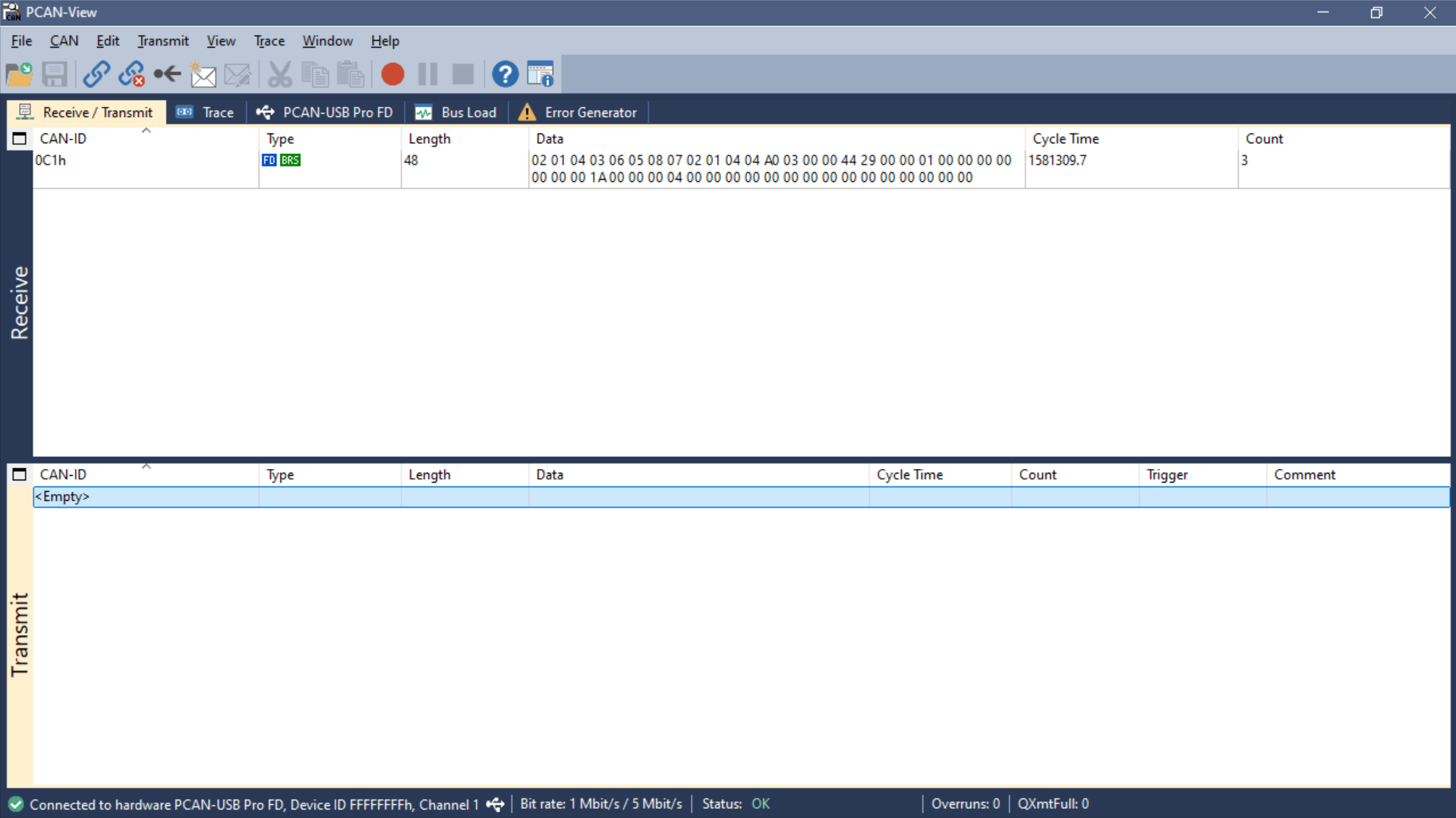

during this connection state only, I am getting the error mentioned above. and one data packet 0C1h is received.

connection - 2:

CANA_H - CANL

CANA_L - CANH

GND - GND

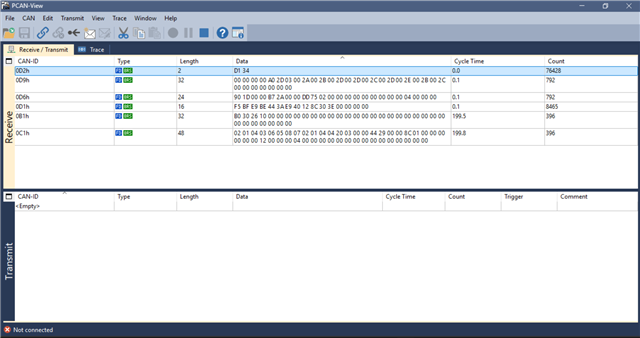

during this connection state, I don't see any of the data coming from CAN using peak view.

I have double checked for connectivity and lose contact but there is no such thing.

Also for switch cfg S1 - XDS mode, S2 - PMIC SPI mode

also I have tried to run the demo in ccs but error follows

I am sending the cli without enabling heatmap only.

sensorStop

flushCfg

dfeDataOutputMode 1

channelCfg 15 15 0

adcCfg 2 0

adcbufCfg -1 1 0 0 1

lowPower 0 0

profileCfg 0 77 7 7 20.81 0 0 8.883 0 384 30000 0 0 36

chirpCfg 0 5 0 0 0 0 0 15

frameCfg 0 5 128 0 384 50 1 0

guiMonitor -1 0 0 0 0 0 0

cfarCfg -1 1 3 16 0 0 1 24.0 0 7 0 1

cfarCfg -1 0 3 16 0 0 1 15.0 0 7 0 0

compressionCfg -1 1 0 0.5 8

intfMitigCfg -1 15 18

localMaxCfg -1 6 40

antennaCalibParams 0 1 0 1 0 1 0 1 0 1 0 1 0 1 0 1 0 1 0 1 0 1 0 1 0 1 0 1 0 1 0 1

measureRangeBiasAndRxChanPhase 0 1.5 0.2

analogMonitor 0 0

calibData 0 0 0

aoaFovCfg -1 -90 90 -90 90

sensorStart

Also during checking for other e2e post someone faced same error but I didn't see how the error has been solved.

e2e link : https://e2e.ti.com/support/sensors-group/sensors/f/sensors-forum/1369944/awr2944evm-sample-applications-not-working

e2e link : AWR2944EVM: CAN output - Sensors forum - Sensors - TI E2E support forums

e2e link : AWR2944EVM: Cannot configure non-standard baud rate 3125000 in Linux Environment - Sensors forum - Sensors - TI E2E support forums

The above mentioned e2e links are the threads whose faced similar error, could you please instruct us where or what we're doing wrong.

Regards,

Eswaramoorthy Sugavanam