Hi,

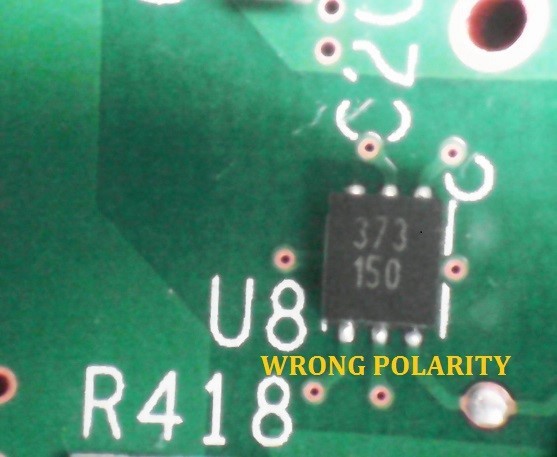

We have repeating issue in our manufacturing related to polarity of TI product LM26LVCISD-150/NOPB. Based on the physical marking, the pin 1 is not clearly indicated on the upper body. This has caused high risk of wrong polarity of the chip being mounted on board. Understood that the pin 1 can be interpreted from the bottom of the chip but this is impractical. We would like to seek TI's initiative to improve this by adding a visible dot marking to clearly indicate the location of pin 1 on the chip.

Pin 1 marking not visible on the upper body.

Difficult to locate the pin 1 location from the pad layout (bottom of the chip)

Thank you.