Hi Subhash,

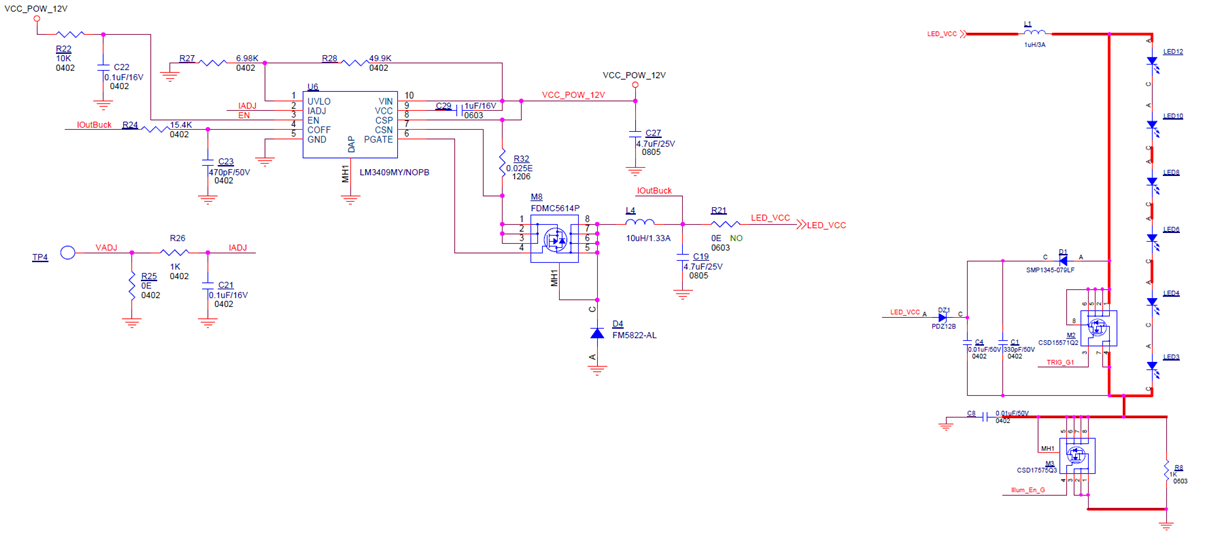

I want to use an aluminum substrate PCB for dissipating the heat of LEDs.

There are only several LEDs on the aluminum substrate board.

The other LED driving parts(include inductors,MOSFETs…etc) are on another board.

Then the aluminum substrate board connect to another board with a cable.

Please confirm if they can work well?