Other Parts Discussed in Thread: AWR1642, , AWR1243

Dear TI support ,

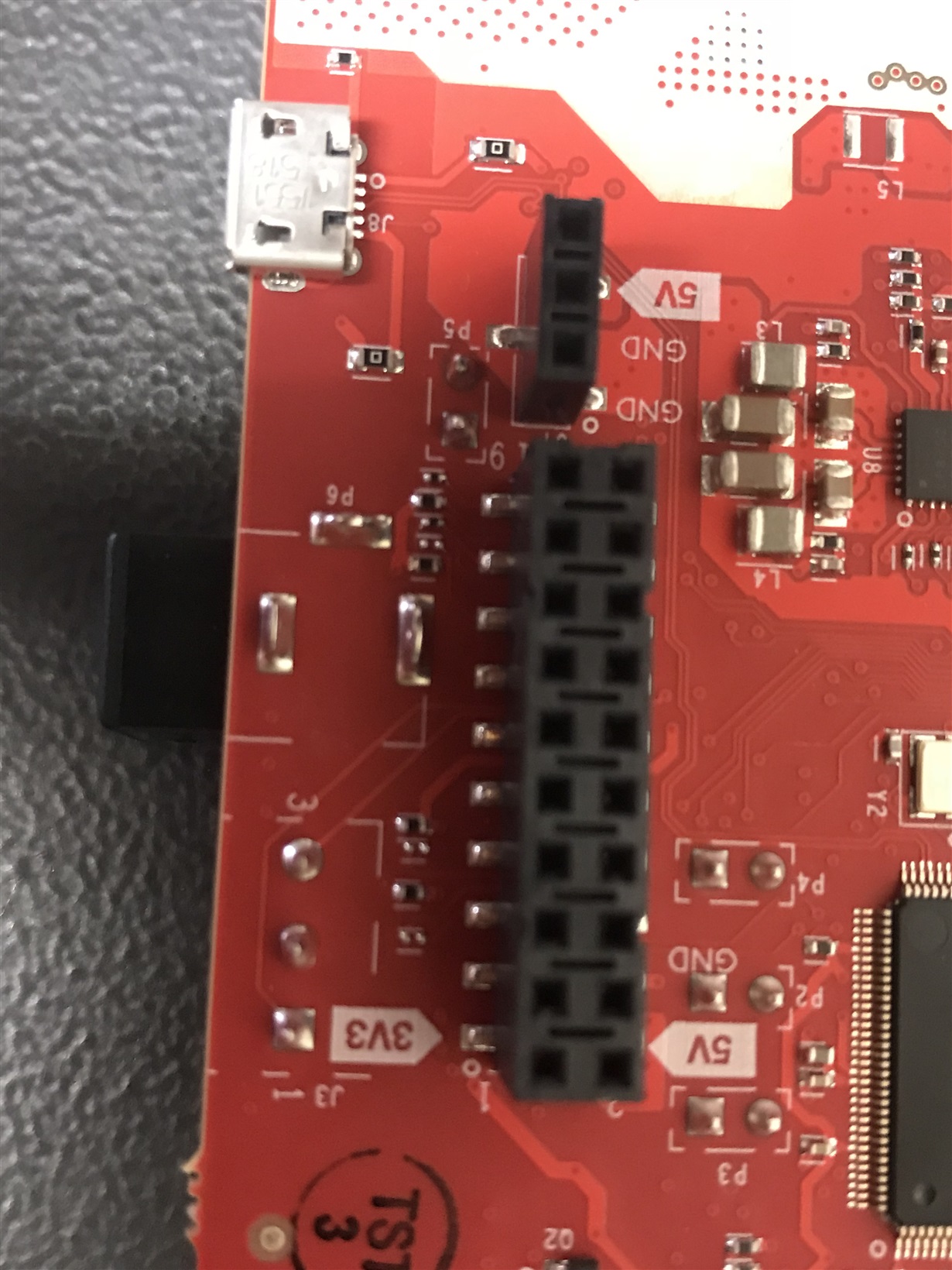

I have TSW1400EVM, MMWAVE DEVPACK and AWR1642BOOST connected together. Software triggering has been working but i still have no luck getting the hardware trigger. I was trying to do it through EXT_TRG_INPUT, which is an SMA connector on TSW1400EVM probably (naively) thinking it somehow has been connected to the appropriate pin (SYNC_IN?) on AWR1642BOOST.Schematic tracing shows there is no connection or output signal from the FPGA that is driving SYNC_In on AWR1642, so i concluded from other posts (for different device, not AWR1642, that the hardware trigger should be done directly on the AWR1642 (SYNC_IN not on TSW1400EVM). Is this correct? Any details for example having to fit a 0 ohm jumper/resistor?

Or, could i do the trigger from TSW1400EVM, given that EXT_TRG_INPUT can drive SYNC1-4 on TSW1400EVM, would it make sense to get SYNC1-4 wired to drive d SYNC_IN on AWR1642? I'm not sure if this would be OK as we might have take into account the LVDS transmission time?

If i were to hardware trigger directly on AWR1642 SYNC_IN, is there any handshake/synchronisation signal between AWR1642 and TSW1400EVM, hence the connection i was thinking above will not be necessary?

How does changing Trigger Select to Hardware trigger in Radar Studio affect Trigger Option in Data Capture Option in HIgh Speed Data Converter?-which is required to be ticked for hardware triggering as per slwu087d (or do they not talking each other?)-i believe these 2 softwares talk each other when Setup TSW1400 get executed?My observation shows that changing to hardware trigger in radar studio resulted in changes in Trigger Option changes in HIgh Speed Data Converter?

For TSW1400EVM the hardware requirement for trigger is also not 100% clear. The manual above specifies 1.8V, but if you look at the schematics its on the 3V bank of the FPGA.

i also have a second set of TSW1400EVM, MMWAVE DEVPACK and AWR1642BOOST and planing to connect (using SMA cables) the SYNC1(or 2,3,4) of one to EXT_TRG_INPUT of my other set as illustrated in slwu087d(master slave operation)

SUMMARY:

I need a hardware trigger for AWR1642(BOOST). At minimum, i just need it to send a frame (transmit). However because i also have TSW1400EVM i definitely want to do some data capture as well.

Any wiring requirement for doing the above?(it seems to be required from what i can see?). Please specify the correct sequence in Radar Studio (or if Lua scripting is required) and High Speed Data Converter (if required).

If triggering through TSW1400EVM is possible (probably need wiring), then please clarify if it's 1.8V or 3.3V (question raised above). As you know with FPGA is not easy to work out as the I/O's are programmable

Last question what is the marking for silicon ES 1.0 vs ES 2.0

Thanks! I have been posting on some other posts with no luck and unable to find any answer on this forum. I also submitted SR # 1-3694176368

I understand the the device is still in preview mode hence there are very limited reference at this stage. We have however spent around $4,000 to purchase 2 sets of TSW1400EVM, MMWAVE DEVPACK and AWR1642BOOST

Best Regards