Hello,

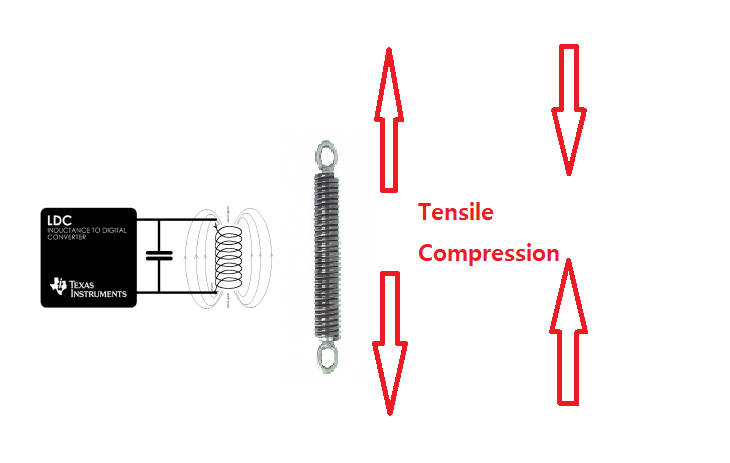

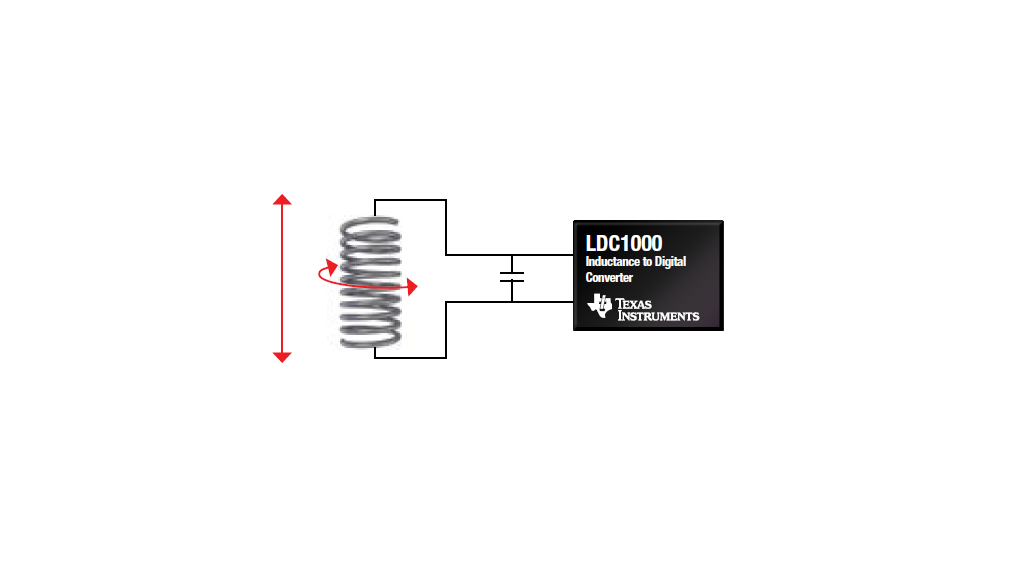

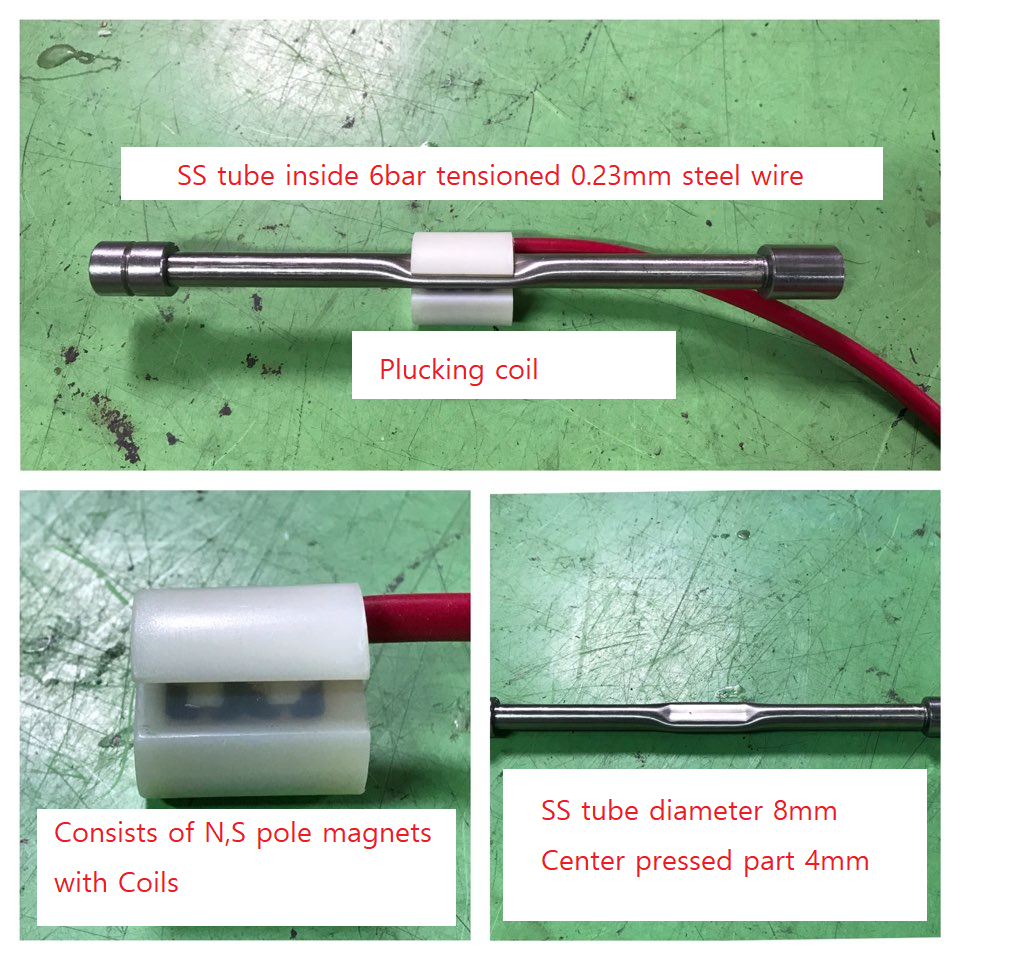

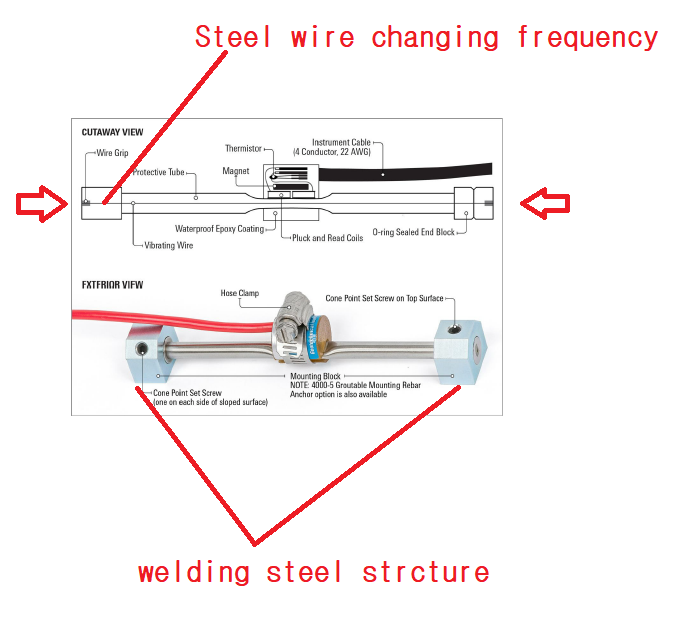

Can the LDC1000 circuit measure spring tensile and compression movement?

If so, What is resolution and maximum monitoring range available?

What is maximum measuring distance available between coil and target spring ?

How can it display in the program if it detected 0.2mm changing against 10.2mm deformation length from 10mm original length?

Thanks.