Other Parts Discussed in Thread: PGA450-Q1, PGA460, PGA460-Q1, TPS4H000-Q1

Hello TI -Team ,

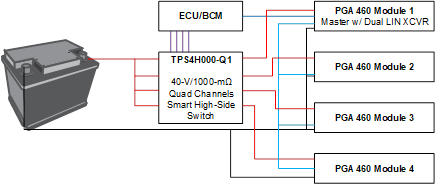

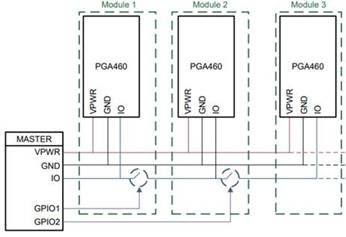

i ma working on Automotive ADAS application project for reverse park assist , we are using 4 ultrasonic sensors , i have gone through the PGA450-Q1 and PGA460 also , we have a master ECU connected to LIN network , we are looking for cost effective solution.

Proposal 1 : with PGA450-Q1 :

since PGA450-q1 is having 8-bit MCU and LIN interface can we connect directly the IC and start reading the data from all the ICs ? if yes how to differentiate the data coming from which sensor , does each IC has its own NAD or do you have other proposal .

I can see this IC is bit costlier as well , we do not require the 8- bit MCU again , need to qualify for functional safety standards also . So we are looking for IC with DSP and EEPROM to store data so that can be read via SPI /I2c

Proposal 2 : with PGA 460 - Q1 :

This IC is suitable for the application since it is not having any MCU , and a discrete Solution with DSP and EEPROM , but problem is how to interface with my LIN Master ECU , since it is not having any LIN compatible .

Kindly suggest your proposal.

Thanks and Regards

Shyam Prasad