Hi,

I am having a problem with TMP235. I am doing some radiated immunity tests on one of my boards and noticed at frequencies between about 330MHz and 600MHz a temperature drift read by the component from 2 to 3°C.

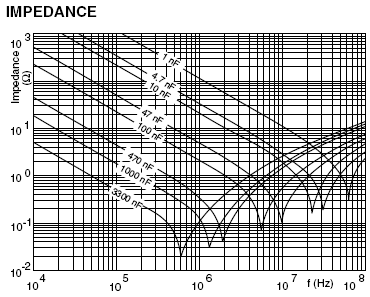

I initially assumed a drift of the A/D stage, however following further tests, even replacing the sensor with a resistive divider, it seems that the problem is a drift of the component itself at these frequencies. I provided a power supply bypass at the input with two 100nF // 100pF capacitors, at the output we have a 100pF capacitor directed between Vout and GND, then an R-C filter as suggested in the datasheet positioned near the A / D. In the position where the TMP235 is mounted it is not possible to have a homogeneous diffuse ground plane as we are close to the cold junction of a thermocouple, however below the component there is a zero volt plane.

Do you have any indications or application notes more specific than the datasheet dedicated to how to make this specific type of component more immune? Thanks,

Antonio