Hello,

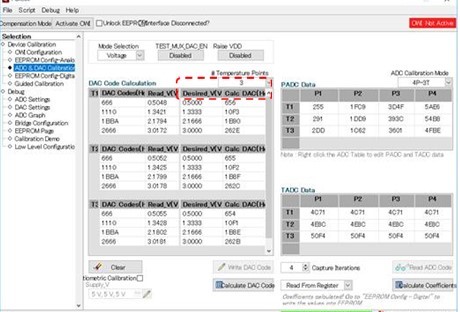

I don't know how calculate AD value of PGA300 EEPROM from PGA300 GUI voltage value. I would like to write AD value to PGA300 EEPROM by OWI communication that I prepared instead of GUI. The following are the items I want to attempt, and the attached file is a example.

・Normal Pressure upper value

・Normal Pressure lower value

・Clamp Vlue -lower

・Fault configurable value