Hi

I am Andy

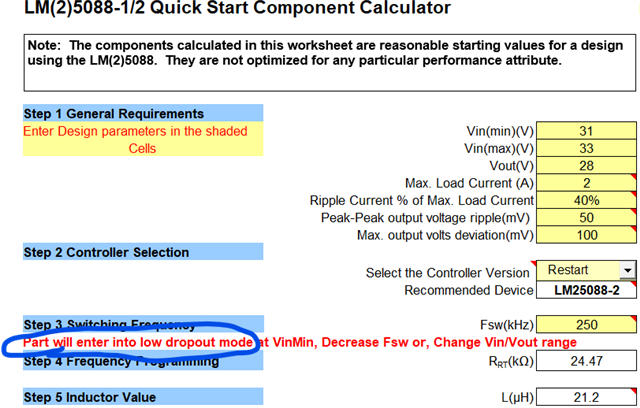

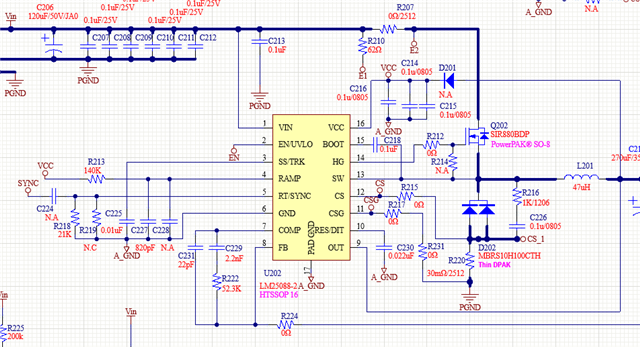

I created a DD buck converter with LM25088QMH-2.

Vin 31V, Vo 28V/2A

First Step

I set the Ramp-R213 4M-ohm and SET RT 47k-ohm, set the inductor 15uH.

The buck converter runs in DCM 0A-2A.

Everything is good but the output ripple, the ripple is almost 100mV.

It is over our spec.

The frequency runs from about 134kHz to 30kHz.

And then, I tried to set the Ramp-R213 to 62k-ohm.

It runs CCM, but the duty is clamped at 50%-60%, so that the Vout is droped.

Could the fequency be fixed or the duty up to 95%?

7.3.6 Dropout Voltage Reduction

The LM25088 features unique circuitry to reduce the dropout voltage. Dropout voltage is defined as the

difference between the minimum input voltage to maintain regulation and the output voltage (VIN(min) – VOUT).

Dropout voltage thus determines the lowest input voltage at which the converter maintains regulation. In a

buck converter, dropout voltage primarily depends upon the maximum duty cycle. The maximum duty cycle is

dependent on the oscillator frequency and minimum off time.

An approximation for the dropout voltage is:

Dropout_Voltage = VOUT x

TOSC - TOFF(max)

TOFF(max)

(4)

where

• TOSC is 1 / fSW.

• TOFF (max) is the forced off time (280-ns typical, 365-ns maximum).

• fSW and TOSC are the oscillator frequency and oscillator period, respectively.

From the above equation, it can be seen that for a given output voltage, reducing the dropout voltage requires

either reducing the forced off time or oscillator frequency (1 / tOSC). The forced off time is limited by the time

required to replenish the bootstrap capacitor and time required to sample the re-circulating diode current. The

365-ns forced off time of the LM25088 controller is a good trade-off between these two requirements. Thus,

the LM25088 reduces dropout voltage by dynamically decreasing the operating frequency during dropout. The

dynamic frequency control (DFC) is achieved using a dropout monitor, which detects a dropout condition and

reduces the operating frequency. The operating frequency continues to decrease with decreasing input voltage

until the frequency falls to the minimum value set by the DFC circuitry.

fSW(minDFC) ≊ 1/3 × fSW(nominal) (5)

If the VIN voltage continues to fall below this point, output regulation can no longer be maintained. The oscillator

frequency reverts back to the nominal operating frequency set by the RT resistor when the input voltage

increases above the dropout range. DFC circuitry does not affect the PWM during normal operating conditions.