Other Parts Discussed in Thread: DLP-7970ABP

Hi Support,

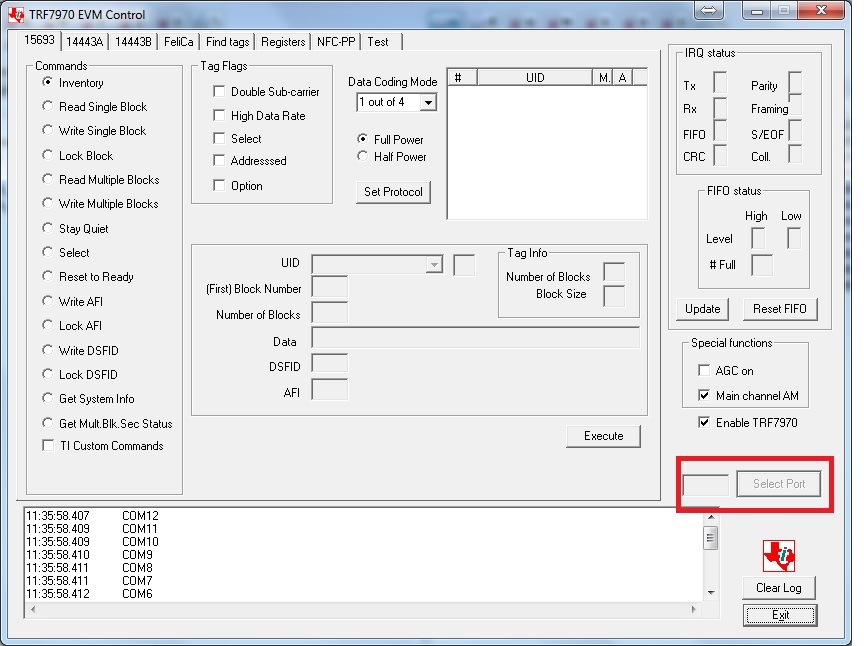

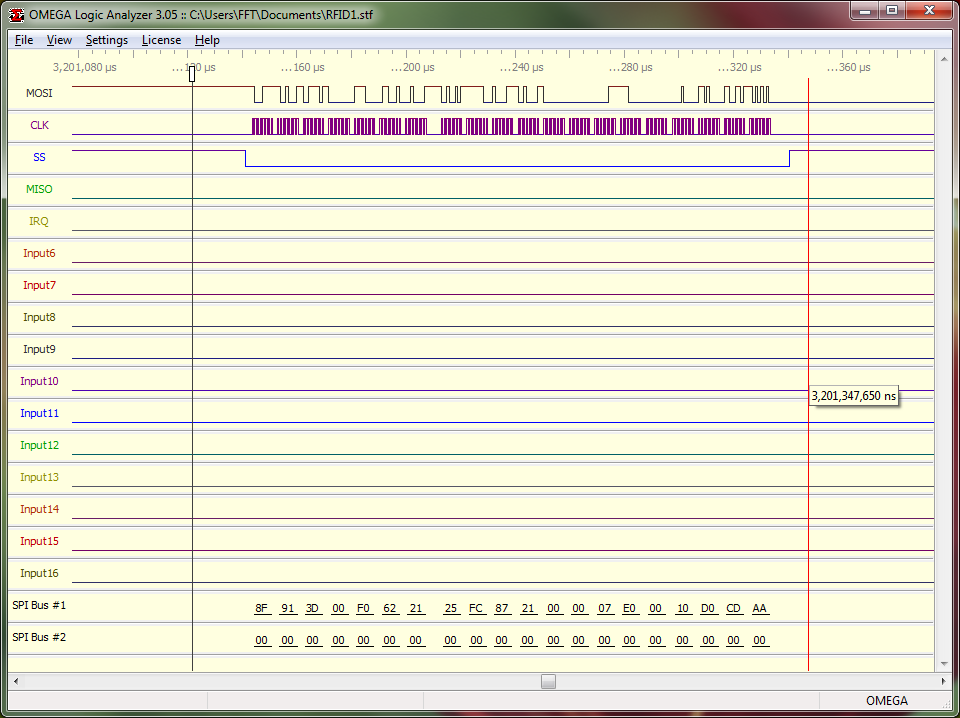

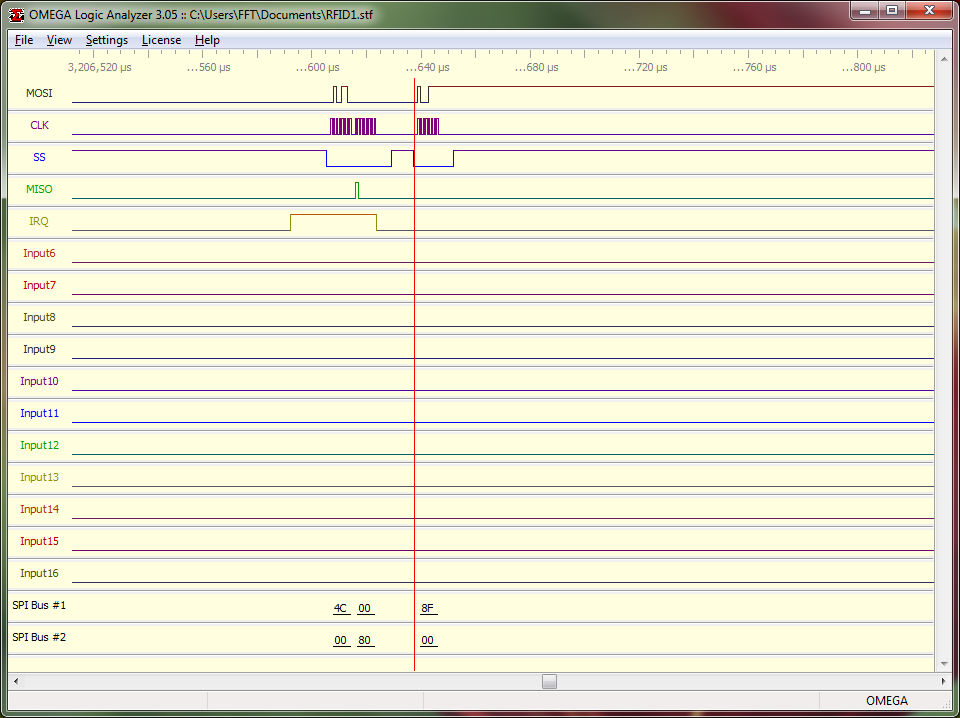

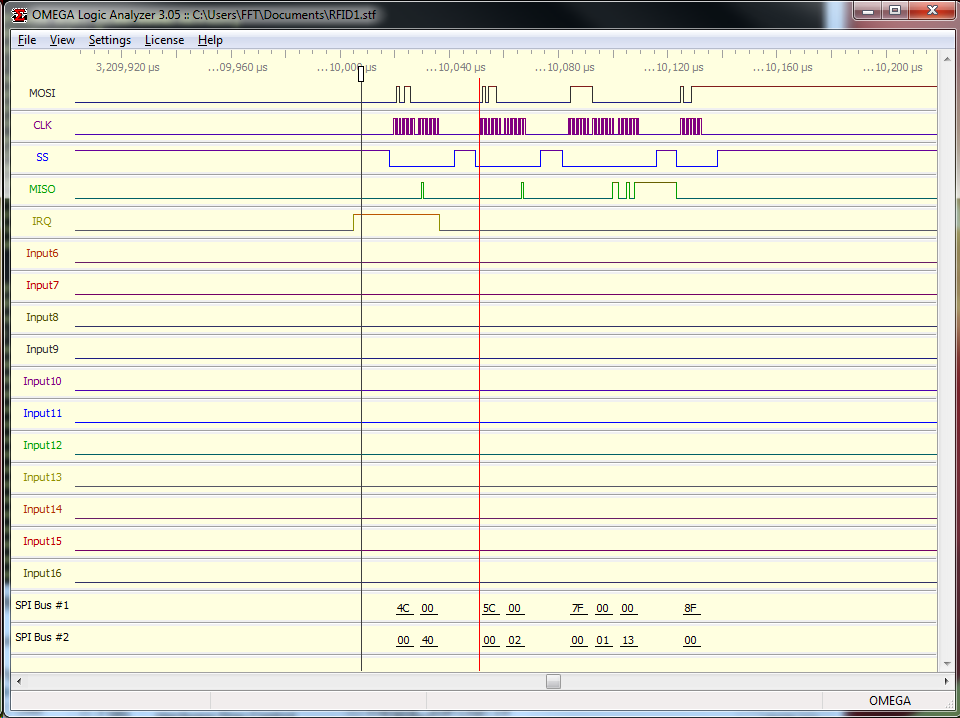

my customer is testing TRF7970A connected on on SPI interface. They need to know if EN input can be connected to Vcc and EN2 to GND permanently, or if they need to change logic if they need to communicate with RFID tag. They also need to better understand the command sequence to be used with TRF controller to write and read data from user memory.

Thanks and regards,

Alberto