Hi,

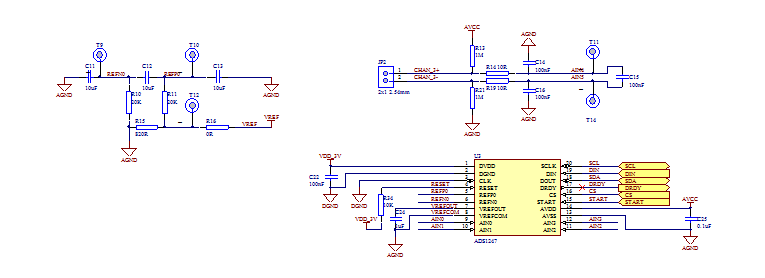

I am trying to use an ADS1247 to measure small voltage generated by a thermocouple sensor. I have setup the device such that I initialize it by doing a RESET (0x06) followed by 0x40 to write setup and then a constant conversion to see the output. I have sent the following

WriteSPI(0x40); //Write CMD

WriteSPI(0x03); //Number of register to write 4 so 4-1, 3 to be sent as per datasheet

WriteSPI(0x01); //MUX Control Register AN0 POS and AN1 NEG

WriteSPI(0x00); //BIAS No BIAS set

WriteSPI(0x35); //MULTIPLEXER Control: Internal Oscillator, Internal Ref ON during Conversion, Internal Ref selected, Monitor Control REF0

WriteSPI(0x00); //Control PGA=1 DR =5SPS

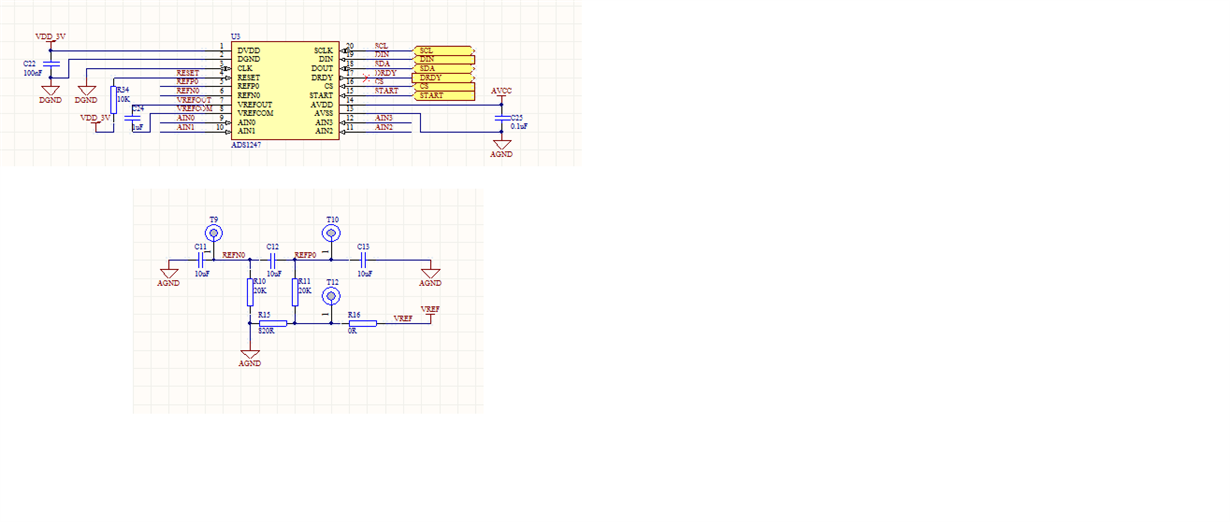

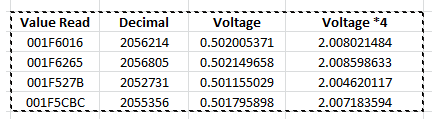

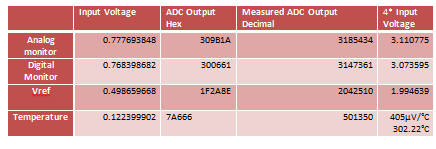

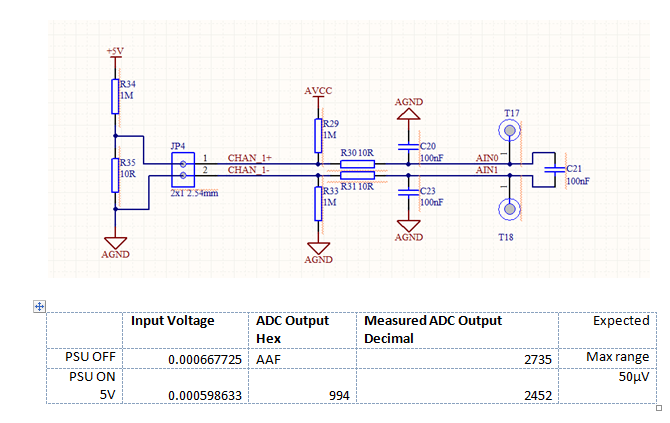

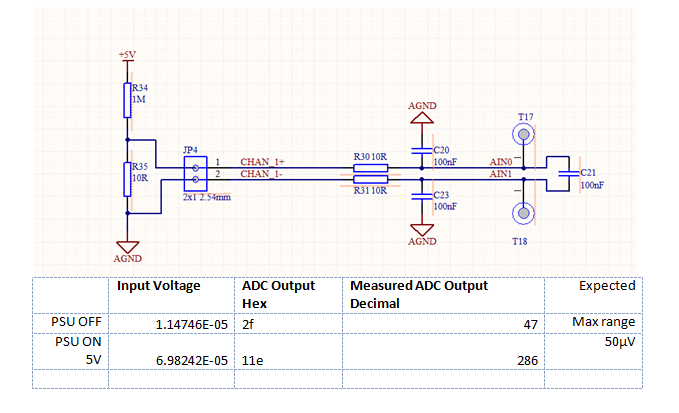

When looking at the output I was expecting the 1/4 of Vref which should be 512mV or on the reading from the ADC a value near 0x200000 however I am not getting such value but 0x7FFFFF. Below is the schematic of the hardware used

Thank you for your help