Hi,

I am using C2000 Launchpad to acquire a waveform through analog channel 1, using EPWM to trigger ADCINT1.

I modified the existing example program adc_temp_sensor. CPU clock frequency is set at 50 MHz. The value loaded into CMPA register is 50 so that I get an ADC sampling rate of 1MHz.

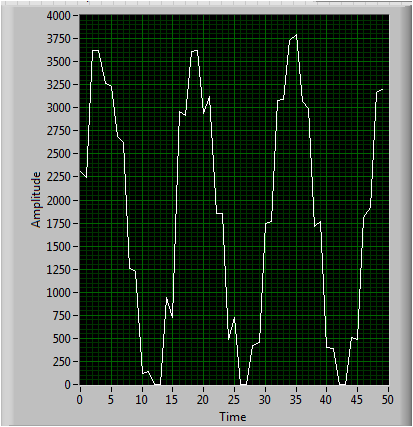

However, the acquired waveform when plotted in the Graph facility available in CCS looks very distorted.

Kindly help with this issue. Thanks in advance. Following is the code:

****************************

//#############################################################################

//

// File: f2802x_examples_ccsv4/adc_temp_sensor/Example_F2802xAdcTempSensor.c

//

// Title: F2802x ADC Temperature Sensor Example Program.

//

// Group: C2000

// Target Device: TMS320F2802x

//

//! \addtogroup example_list

//! <h1>ADC Temperature Sensor</h1>

//!

//! Interrupts are enabled and the ePWM1 is set up to generate a periodic

//! ADC SOC interrupt - ADCINT1. One channel is converted - ADCINA5, which is internally

//! connected to the temperature sensor.

//!

//! Watch Variables:

//!

//! - TempSensorVoltage[10] Last 10 ADCRESULT0 values

//! - ConversionCount Current result number 0-9

//! - LoopCount Idle loop counter

//

// (C) Copyright 2012, Texas Instruments, Inc.

//#############################################################################

// $TI Release: LaunchPad f2802x Support Library v100 $

// $Release Date: Wed Jul 25 10:45:39 CDT 2012 $

//#############################################################################

//#############################################################################

//

// File: f2802x_examples_ccsv4/adc_temp_sensor/Example_F2802xAdcTempSensor.c

//

// Title: F2802x ADC Temperatrue Sensor Example Program.

//

// Group: C2000

// Target Device: TMS320F2802x

//

//! \addtogroup example_list

//! <h1>ADC Temperatrue Sensor</h1>

//!

//! Interrupts are enabled and the ePWM1 is set up to generate a periodic

//! ADC SOC interrupt - ADCINT1. One channel is converted - ADCINA5, which is internally

//! connected to the temperature sensor.

//!

//! Watch Variables:

//!

//! - TempSensorVoltage[10] Last 10 ADCRESULT0 values

//! - ConversionCount Current result number 0-9

//! - LoopCount Idle loop counter

//

// (C) Copyright 2012, Texas Instruments, Inc.

//#############################################################################

// $TI Release: LaunchPad f2802x Support Library v100 $

// $Release Date: Wed Jul 25 10:45:39 CDT 2012 $

//#############################################################################

#include "DSP28x_Project.h" // Device Headerfile and Examples Include File

#include "f2802x_common/include/adc.h"

#include "f2802x_common/include/clk.h"

#include "f2802x_common/include/flash.h"

#include "f2802x_common/include/gpio.h"

#include "f2802x_common/include/pie.h"

#include "f2802x_common/include/pll.h"

#include "f2802x_common/include/wdog.h"

// Prototype statements for functions found within this file.

interrupt void adc_isr(void);

// Global variables used in this example:

uint16_t LoopCount;

uint16_t ConversionCount;

uint16_t Result[50];

ADC_Handle myAdc;

CLK_Handle myClk;

FLASH_Handle myFlash;

GPIO_Handle myGpio;

PIE_Handle myPie;

PWM_Handle myPwm;

void main()

{

CPU_Handle myCpu;

PLL_Handle myPll;

WDOG_Handle myWDog;

// Initialize all the handles needed for this application

myAdc = ADC_init((void *)ADC_BASE_ADDR, sizeof(ADC_Obj));

myClk = CLK_init((void *)CLK_BASE_ADDR, sizeof(CLK_Obj));

myCpu = CPU_init((void *)NULL, sizeof(CPU_Obj));

myFlash = FLASH_init((void *)FLASH_BASE_ADDR, sizeof(FLASH_Obj));

myGpio = GPIO_init((void *)GPIO_BASE_ADDR, sizeof(GPIO_Obj));

myPie = PIE_init((void *)PIE_BASE_ADDR, sizeof(PIE_Obj));

myPll = PLL_init((void *)PLL_BASE_ADDR, sizeof(PLL_Obj));

myPwm = PWM_init((void *)PWM_ePWM1_BASE_ADDR, sizeof(PWM_Obj));

myWDog = WDOG_init((void *)WDOG_BASE_ADDR, sizeof(WDOG_Obj));

// Step 1. Initialize System Control:

// PLL, WatchDog, enable Peripheral Clocks

// This example function is found in the F2802x_SysCtrl.c file.

// InitSysCtrl();

// Perform basic system initialization

WDOG_disable(myWDog);

CLK_enableAdcClock(myClk);

(*Device_cal)();

//Select the internal oscillator 1 as the clock source

CLK_setOscSrc(myClk, CLK_OscSrc_Internal);

// Setup the PLL for x10 /2 which will yield 50Mhz = 10Mhz * 10 / 2

PLL_setup(myPll, PLL_Multiplier_10, PLL_DivideSelect_ClkIn_by_2);

// Disable the PIE and all interrupts

PIE_disable(myPie);

PIE_disableAllInts(myPie);

CPU_disableGlobalInts(myCpu);

CPU_clearIntFlags(myCpu);

// If running from flash copy RAM only functions to RAM

#ifdef _FLASH

memcpy(&RamfuncsRunStart, &RamfuncsLoadStart, (size_t)&RamfuncsLoadSize);

#endif

// Step 2. Initialize GPIO:

// This example function is found in the F2802x_Gpio.c file and

// illustrates how to set the GPIO to it's default state.

// InitGpio(); // Skipped for this example

// Step 3. Clear all interrupts and initialize PIE vector table:

// Disable CPU interrupts

// DINT;

// Initialize the PIE control registers to their default state.

// The default state is all PIE interrupts disabled and flags

// are cleared.

// This function is found in the F2802x_PieCtrl.c file.

// InitPieCtrl();

// Disable CPU interrupts and clear all CPU interrupt flags:

// IER = 0x0000;

// IFR = 0x0000;

// Initialize the PIE vector table with pointers to the shell Interrupt

// Service Routines (ISR).

// This will populate the entire table, even if the interrupt

// is not used in this example. This is useful for debug purposes.

// The shell ISR routines are found in F2802x_DefaultIsr.c.

// This function is found in F2802x_PieVect.c.

// InitPieVectTable();

PIE_setDebugIntVectorTable(myPie);

PIE_enable(myPie);

// Interrupts that are used in this example are re-mapped to

// ISR functions found within this file.

EALLOW; // This is needed to write to EALLOW protected register

// PieVectTable.ADCINT1 = &adc_isr;

((PIE_Obj *)myPie)->ADCINT1 = &adc_isr;

EDIS; // This is needed to disable write to EALLOW protected registers

// Step 4. Initialize the ADC:

// This function is found in F2802x_Adc.c

// InitAdc(); // For this example, init the ADC

ADC_enableBandGap(myAdc);

ADC_enableRefBuffers(myAdc);

ADC_powerUp(myAdc);

ADC_enable(myAdc);

ADC_setVoltRefSrc(myAdc, ADC_VoltageRefSrc_Int);

// Step 5. Configure ADC to sample the temperature sensor on ADCIN5:

// The output of Piccolo temperature sensor can be internally connected to the ADC through ADCINA5

// via the TEMPCONV bit in the ADCCTL1 register. When this bit is set, any voltage applied to the external

// ADCIN5 pin is ignored.

// EALLOW;

// AdcRegs.ADCCTL1.bit.TEMPCONV = 1; //Connect internal temp sensor to channel ADCINA5.

// ADC_enableTempSensor(myAdc);

// EDIS;

// Step 6. Continue configuring ADC to sample the temperature sensor on ADCIN5:

// Since the temperature sensor is connected to ADCIN5, configure the ADC to sample channel ADCIN5

// as well as the ADC SOC trigger and ADCINTs preferred. This example uses EPWM1A to trigger the ADC

// to start a conversion and trips ADCINT1 at the end of the conversion.

//Note: The temperature sensor will be double sampled to apply the workaround for rev0 silicon errata for the ADC 1st sample issue

// EALLOW;

// AdcRegs.ADCCTL1.bit.INTPULSEPOS = 1; //ADCINT1 trips after AdcResults latch

ADC_setIntPulseGenMode(myAdc, ADC_IntPulseGenMode_Prior);

// AdcRegs.INTSEL1N2.bit.INT1E = 1; //Enabled ADCINT1

ADC_enableInt(myAdc, ADC_IntNumber_1);

// AdcRegs.INTSEL1N2.bit.INT1CONT = 0; //Disable ADCINT1 Continuous mode

ADC_setIntMode(myAdc, ADC_IntNumber_1, ADC_IntMode_ClearFlag);

// AdcRegs.INTSEL1N2.bit.INT1SEL = 1; //setup EOC1 to trigger ADCINT1 to fire

ADC_setIntSrc(myAdc, ADC_IntNumber_1, ADC_IntSrc_EOC1);

// AdcRegs.ADCSOC0CTL.bit.CHSEL = 5; //set SOC0 channel select to ADCINA5 (which is internally connected to the temperature sensor)

ADC_setSocChanNumber (myAdc, ADC_SocNumber_0, ADC_SocChanNumber_A1);

// AdcRegs.ADCSOC1CTL.bit.CHSEL = 5; //set SOC1 channel select to ADCINA5 (which is internally connected to the temperature sensor) errata workaround

ADC_setSocChanNumber (myAdc, ADC_SocNumber_1, ADC_SocChanNumber_A1);

// AdcRegs.ADCSOC0CTL.bit.TRIGSEL = 5; //set SOC0 start trigger on EPWM1A

ADC_setSocTrigSrc(myAdc, ADC_SocNumber_0, ADC_SocTrigSrc_EPWM1_ADCSOCA);

// AdcRegs.ADCSOC1CTL.bit.TRIGSEL = 5; //set SOC1 start trigger on EPWM1A errata workaround

ADC_setSocTrigSrc(myAdc, ADC_SocNumber_1, ADC_SocTrigSrc_EPWM1_ADCSOCA);

// AdcRegs.ADCSOC0CTL.bit.ACQPS = 6; //set SOC0 S/H Window to 7 ADC Clock Cycles, (6 ACQPS plus 1)

ADC_setSocSampleWindow(myAdc, ADC_SocNumber_0, ADC_SocSampleWindow_7_cycles);

// AdcRegs.ADCSOC1CTL.bit.ACQPS = 6; //set SOC1 S/H Window to 7 ADC Clock Cycles, (6 ACQPS plus 1) errata workaround

ADC_setSocSampleWindow(myAdc, ADC_SocNumber_1, ADC_SocSampleWindow_7_cycles);

// EDIS;

// Step 7. User specific code, enable interrupts:

// Enable ADCINT1 in PIE

// PieCtrlRegs.PIEIER1.bit.INTx1 = 1; // Enable INT 1.1 in the PIE

PIE_enableAdcInt(myPie, ADC_IntNumber_1);

// IER |= M_INT1; // Enable CPU Interrupt 1

CPU_enableInt(myCpu, CPU_IntNumber_10);

// EINT; // Enable Global interrupt INTM

CPU_enableGlobalInts(myCpu);

// ERTM; // Enable Global realtime interrupt DBGM

CPU_enableDebugInt(myCpu);

LoopCount = 0;

ConversionCount = 0;

CLK_enablePwmClock(myClk,PWM_Number_1);

// Assumes ePWM1 clock is already enabled in InitSysCtrl();

// EPwm1Regs.ETSEL.bit.SOCAEN = 1; // Enable SOC on A group

PWM_enableSocAPulse(myPwm);

// EPwm1Regs.ETSEL.bit.SOCASEL = 4; // Select SOC from from CPMA on upcount

// PWM_setSocAPulseSrc(myPwm, PWM_SocPulseSrc_CounterEqualCmpAIncr);

PWM_setSocAPulseSrc(myPwm, PWM_SocPulseSrc_CounterEqualPeriod);

// EPwm1Regs.ETPS.bit.SOCAPRD = 1; // Generate pulse on 1st event

PWM_setSocAPeriod(myPwm, PWM_SocPeriod_FirstEvent);

// EPwm1Regs.CMPA = 0x0080; // Set compare A value

((PWM_Obj *)myPwm)->CMPA = 0x0080;

// EPwm1Regs.TBPRD = 0xFFFF; // Set period for ePWM1

// PWM_setPeriod(myPwm, 0x00FF);

PWM_setPeriod(myPwm, 0x0032);

// EPwm1Regs.TBCTL.bit.CTRMODE = 0; // count up and start

PWM_setCounterMode(myPwm, PWM_CounterMode_Up);

CLK_enableTbClockSync(myClk);

// Wait for ADC interrupt

for(;;)

{

LoopCount++;

}

}

interrupt void adc_isr(void)

{

// TempSensorVoltage[ConversionCount] = AdcResult.ADCRESULT1; //discard ADCRESULT0 as part of the workaround to the 1st sample errata for rev0

Result[ConversionCount] = ADC_readResult(myAdc, ADC_ResultNumber_1);

// If 50 conversions have been logged, start over

if(ConversionCount == 50)

{

ConversionCount = 0;

}

else ConversionCount++;

// AdcRegs.ADCINTFLGCLR.bit.ADCINT1 = 1; //Clear ADCINT1 flag reinitialize for next SOC

ADC_clearIntFlag(myAdc, ADC_IntNumber_1);

// PieCtrlRegs.PIEACK.all = PIEACK_GROUP1; // Acknowledge interrupt to PIE

PIE_clearInt(myPie, PIE_GroupNumber_10);

return;

}