Hi!

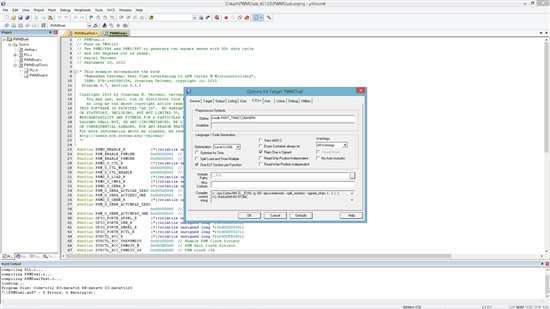

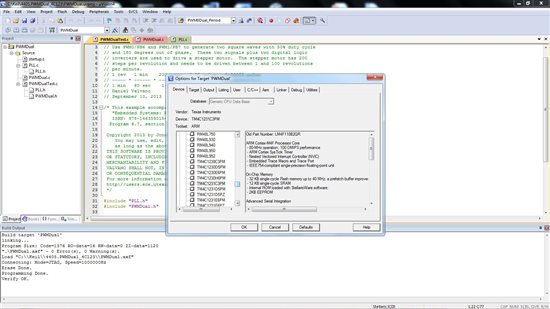

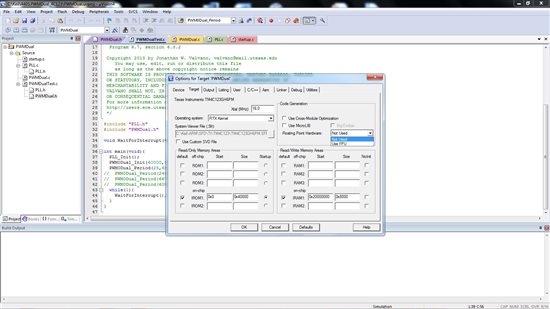

I'm stucked programming with Keil environment as I didn't find any PWM example code for the EK-TM4C123GXL LaunchPad board.

I found some interesting code for Code Composer Studio (CSS) but I can't use it in Keil, could you give me some tips to do so?

Specifically it's about this Labs at TM4C123G_LaunchPad_Workshop:

http://processors.wiki.ti.com/index.php/Getting_Started_with_the_TIVA%E2%84%A2_C_Series_TM4C123G_LaunchPad

and the labs that are inside:

http://software-dl.ti.com/trainingTTO/trainingTTO_public_sw/GSW-TM4C123G-LaunchPad/TM4C123GLaunchPadWorkshopSetup.exe

I'm trying to use the PWM code in Keil but I can't use it.

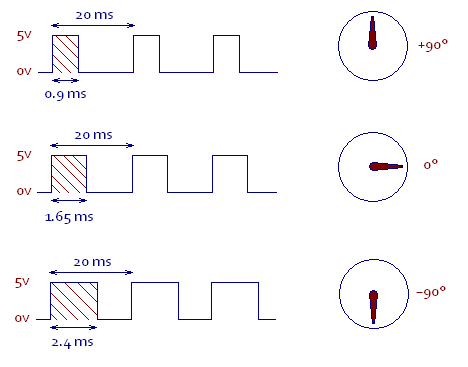

Even better if you have code to run a PWM module in the EK-TM4C123GXL LaunchPad board.

Thanks!

P.S.: after searching several days in Internet for a solution for PWM module at a EK-TM4C123GXL LaunchPad board I didn't find any solution for Keil, so I think it needs a proper and good solution.