This was previously posted in the Low Power RF Proprietary Software & SimpliciTI Forum, in response to Chris's origninal post. I'm reposting it here.

I still need an answer. Thanks.

Hi Chris,

I having the same problem as you.

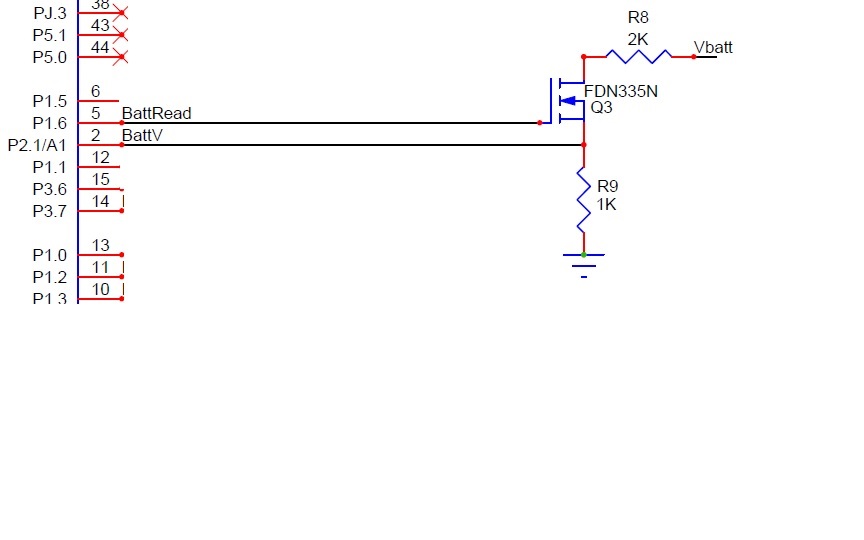

I use P0.3 to read the a battery voltage -- (not the VDD to the cc2510).

I have a resistor divider of 5.11M and 1.27M. P0.3 gets 20% of a 9V battery or ~1.8V.

I can read VDD through the internal VDD/3 input and 1.25 Vref.

Does the ADC need more input current than these megaohm resistors provide?

Can I fix this with a small capacitor in parallel with the 1.27M resistor.

Is this a P0.3 problem? Its the same input as Chris is having problems with.

I only use P0.3.

HEY TI! Please answer this post.

Jack