Test and measurement equipment such as oscilloscopes and waveform generators has its own set of design challenges, from increasing measurement accuracy to providing a low-cost solution to the customer. Measurement accuracy, bandwidth and throughput (or channel count) are critically important to engineers using test equipment, but cost is key as well; after all, managers often must justify equipment purchases by showing that there will be a significant return on investment.

While portable test and measurement equipment is absolutely required for debugging some circuits, adding portability to the feature mix does not help the performance vs. cost trade-off. How should test-equipment manufacturers tackle the design of portable test equipment with these trade-offs in mind?

One way is to simplify and shrink the power-supply portion of the test-equipment system. Numerous power-supply circuits are required to power so much functionality and so many subsystems. If you could use one circuit for most or all rails, the design effort and design cost for the entire power supply would be greatly reduced through the design reuse of that one circuit. This allows faster time to market and less design resources spent on the power supply.

What if this one circuit, in addition to being flexible, was simple to design, very small and efficient, and had low noise? That would enable the test equipment to become portable in short order – keeping efficiency high and noise low while reducing board space occupied and design effort required.

A new MicroSiP power module, the TPS82084, addresses all of these wants and needs. Packaged in a tiny 2.8mm-by-3mm package and occupying 35mm2 total, it requires only two capacitors and two resistors to complete the entire power-supply solution. It includes the power inductor, eliminating the sometimes time-consuming task of selecting one yourself. The two resistors allow you to set the output voltage anywhere below the input voltage – so you can use this one device for all of the system voltage-rails. This saves your R&D budget by reducing the power-supply design effort required.

Figure 1 shows the device, which even has quad flat pack no-lead (QFN)-style mounting for ease of assembly onto the printed circuit board (PCB). A thermal pad allows a low thermal resistance, enabling operation up to its full rated 2A current even above a 100°C ambient temperature without airflow.

Figure 1: The TPS82084 MicroSiP power module features QFN-like pads for easier assembly onto the PCB

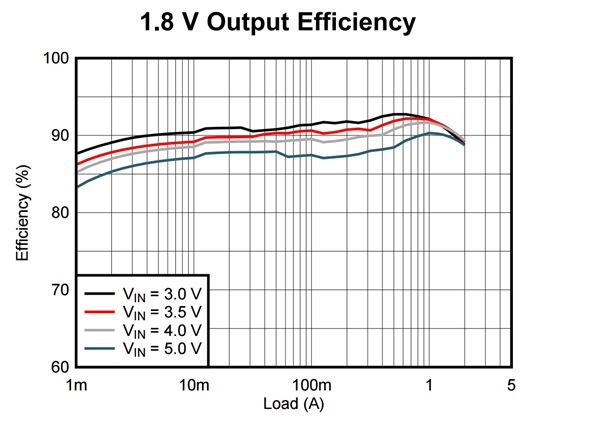

The 17µA quiescent current (IQ) provides high efficiency at light loads, while its DCS-Control topology enables a very low noise power-save mode in order to power subsystems without interference. Figure 2 shows above 90% efficiency at heavier loads. Finally, if firmware upgrades or feature creeps require more than 2A, the TPS82085 provides a pin-to-pin upgrade to 3A.

Figure 2: The TPS82084 provides over 90% efficiency

How can a MicroSiP module enable faster designs in less board space for your test equipment?

Additional resources

- Check out my other blog posts: